You are here: Home »

News

»

Case Study

»

Ion Exchange Resin

»

Solution to the 'Clumping' Phenomenon in Mixed Bed Resin

Solution to the 'Clumping' Phenomenon in Mixed Bed Resin

Mixed bed resin refers to a mixture of a certain ratio of cation and anion exchange resins filled together in a single device, used for exchanging and removing ions in fluids.

It is generally used for water with a low salt content or placed after reverse osmosis or EDI units to reduce the hardness, alkalinity, and both anions and cations in water, turning it into softened or deionized water.

During the ion exchange process, when the H+ and OH- ions inside the resin are exhausted, the resin needs to be regenerated. Before regeneration, the two types of resins must be separated and regenerated using different regenerating agents to prevent the regenerating solution from entering the other type of resin, which could affect the subsequent use of the resin.

Reasons for Indistinct Layering in Mixed Bed Resin Regeneration:

When regenerating mixed bed resin, unclear layering not only leads to a certain degree of decline in the pH value of the produced water, affecting the water quality, but may also result in cation resin being contaminated by alkali and anion resin being contaminated by acid. This leads to a higher salt content in the mixed bed washout water, extending the cleaning time of the resin. At the same time, it can cause cross-contamination during resin regeneration, directly affecting the precision of resin use.

The main reasons for the indistinct layering in mixed bed resin are:

- The flow rate during backwashing is too low, causing insufficient expansion height of the resin.

- Severe crushing of cation resin particles, reducing the density of the broken resin, making it difficult to separate as it gets mixed with the anion resin during layering.

- Related to the degree of resin degradation, the greater the degradation, the easier it is to layer. If the degradation is minor, the ions inside the resin are not exhausted and can continue to be used, making it difficult to layer.

- The phenomenon of clumping occurs in both cation and anion exchange resins after regeneration, making layering difficult.

How to Resolve the 'Clumping' Phenomenon in Mixed Bed Resins:

In practical applications, cation exchange resins release H+ ions, while anion exchange resins release OH- ions. When cation and anion exchange resins are mixed in the mixed bed and come into contact with each other, the H+ ions removed from the cation exchange resin combine with the OH- ions removed from the anion exchange resin to form water.

After losing some cations, the cation exchange resin becomes negatively charged, while the anion exchange resin becomes positively charged. These two types of resins attract each other, leading to the formation of clumps that are difficult to separate. The presence of broken resin fragments and suspended particles can also enhance the 'clumping' effect of the resin. Contamination of the resin can also cause clumping.

The principle behind this is due to electrostatic forces. New resins have very clean surfaces, and the electrostatic force between the cation and anion resins is very strong, making the resin more prone to clumping. It becomes difficult for mixed bed equipment to naturally separate during backwashing. When layering mixed bed resins, adding a certain amount of electrolyte can help. The negatively charged cation resin becomes electrically neutral due to binding with cations (Na+), and the positively charged anion resin becomes neutral due to binding with anions (OH-). As a result, the 'clumped' resins will separate.

Sunresin Polishing Mixed Bed Resin Application Case:

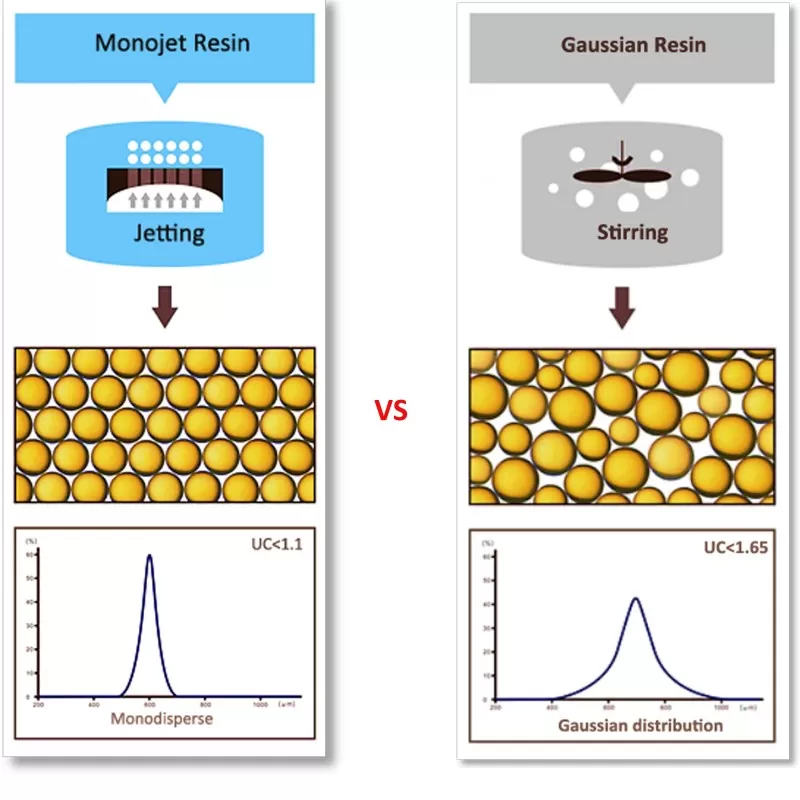

Polishing mixed bed resins are non-regenerable and are commonly used in the preparation of electronic-grade ultrapure water for panel and chip production. Sunresin utilizes its proprietary 'jet granulation' technology and a world-leading resin production line to achieve stable production of uniform particle resins, completely breaking the technical monopoly held by foreign manufacturers in this industry. The Monojet® electronic-grade resin features a high transformation rate, excellent kinetic performance, high cleanliness, extremely low TOC release, and outstanding mechanical strength.

Ultrapure Water Series Resins Ultrapure water, also known as UPW, refers to water with a resistivity of 18.2 MΩ·cm (at 25°C). It is widely used in the production of ultrapure materials or devices, such as in biology, medicine, photovoltaics, panels, semiconductors, etc. Water is pretreated and then desalinated; the desalinated water is further purified using polishing resin to remove trace ions, achieving an output water resistivity of over 18.2 MΩ·cm.

Sunresin has applied uniform particle technology in the field of ultrapure water polishing. Using the 'jet granulation' technology, which fills a domestic technology gap, they produce high-purity, uniform particle cation and anion exchange resins with a uniformity coefficient of <1.1. After being premixed in a certain ratio, these resins can be used in the end stages of ultrapure water preparation systems (refining and polishing process stage) for refinement.

Sunresin at the forefront of innovation in the ultrapure water resin industry, achieving a milestone by matching and even surpassing international standards. Our ultrapure water series resins are not only on par with global competitors but also align with the stringent ASTM technical standards, ensuring unparalleled quality and reliability.

We proudly wear the 'crown' in the ion exchange resin application sector, having perfected the large-scale production of uniform particle white beads. This breakthrough has led to the development of our elite electronic-grade ultrapure water product line, successfully challenging the previously unassailable dominance of certain international entities in this field.

Our achievements in the electronic-grade and nuclear-grade ultrapure water sectors mark a significant industrial breakthrough. By resolving critical dependencies that once constrained domestic advancements, we ensure not only the autonomy but also the robustness of our industrial and supply chains. Sunresin is dedicated to safeguarding and elevating the standards of purity and excellence in the global ultrapure water industry.

Join us in this journey of excellence and innovation. We invite industry leaders, partners, and innovators to explore the superior capabilities of our ultrapure water series resins. With Sunresin, you are not just choosing a product; you're embracing a future of technological superiority and sustainable progress. Contact us today to learn more about our solutions and how they can revolutionize your processes. Let's collaborate to pave the way for a future where quality and reliability are paramount. Reach out to Sunresin – your partner in achieving unparalleled purity and performance.

Free Quote

Resources

Adsorbent Resin

Bio-Pharmaceutical & Life Science

Enzyme Carriers

Hydrometallurgy & Mining

Chelating Resin

Chemical Industry

Chromatographic Media

Wastewater Treatment&Reuse

Food & Beverage Industries

Ion Exchange Resin

Civil & Industry Water Treatment

Equipments And Projects

Plant Extraction

Catalyst Resin

Solid Phase Peptide Synthesis

Product

Application

Contact Us

Sunresin Park,No.135, jinye Road, Xi’an Hi-tech Industrial Development Zone, Shaanxi-710076, China

seplite@sunresin.com

+86-29-89182091

Our Product List

Latest News

26

2024 01

Sunresin has been selected for the Hang Seng China A Specialised & Sophisticated 50 Index

On January 22, Hong Kong's Hang Seng Index Company launched the "Hang Seng China A Specialised & Sophisticated 50 Index", and Sunresin (300487.SZ) was successfully selected as a constituent stock. As of January 12, 2024, the proportion was 2.78%.

27

2023 11

Sunresin Participates in Morgan Stanley 22nd Annual Asia-Pacific Summit

Sunresin, a leading technology company, was invited to attend Morgan Stanley's 22nd Asia-Pacific Summit in Singapore from November 15th to 16th. This summit is a pivotal conference for institutional investors in the Asia-Pacific region.

Leave a Message

Please send any questions you want to know, we will reply to you immediately.

Choose File

Submit