An Innovative Approach to Ion Exchange Introduction to Bipolar Membranes

Sunresin | Electrodialysis with Bipolar Membranes: An Innovative Approach to Ion Exchange

Introduction to Bipolar Membranes

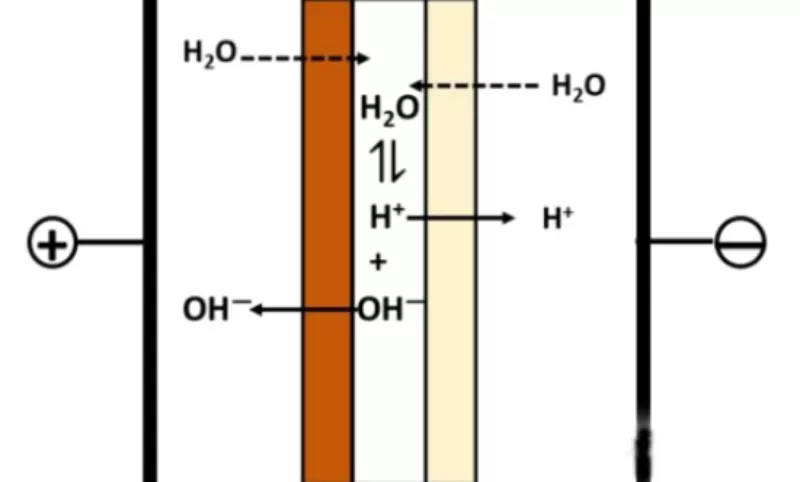

Bipolar membranes represent a leap forward in ion exchange technology. These membranes are engineered by combining anion and cation selective layers with an intermediate interface layer. The unique structure of these membranes allows for the conversion of salts into their respective acids and bases when a reverse voltage is applied across the membrane. This process is facilitated by the migration of charged ions and the dissociation of water molecules at the membrane interface.

Electrodialysis Equipment and Operating Principles

In the realm of bipolar membrane electrodialysis equipment, the configuration is key. The setup includes bipolar membranes alongside cation and anion exchange membranes. This equipment operates under a direct current electric field, prompting charged ions to move selectively through the ion exchange membranes, effectively separating electrolytes within the solution.

In the context of ion exchange processes, envision a system where saline water is channeled through a specialized compartment designed to selectively separate and concentrate different ions present in the water. When electricity is applied, the positive ions (cations) are drawn towards the negatively charged cathode, while the negative ions (anions) are attracted to the positively charged anode. The membranes act as selective barriers, allowing only certain ions to pass through, thus separating the components of the salt water.

Performance Features of Bipolar Membrane Electrodialysis

The performance of bipolar membrane electrodialysis is characterized by:

- Uniform Microstructure: The product's uniform microstructure ensures integrity, preventing shedding or bubbling, and provides excellent stability and longevity.

- Resistance to Harsh Conditions: These membranes exhibit superior resistance to acids, alkalis, and oxidation, making them suitable for use in extreme environments.

- Robust Power Supply: With an impressive mean time between failures (MTBF) of over 1 million hours and a low current harmonic (ITHD), these systems are reliable even in wide temperature and voltage ranges.

- Intelligent Automatic Control Systems: Beyond basic operational needs, these systems can analyze extensive operational data to predict the health of each membrane stack, facilitating timely and effective interventions for intelligent production.

The mean time between failures' is a reliability term that refers to the average time between system breakdowns, indicating the system's reliability. 'Current harmonic' refers to a distortion in the electrical current, and a lower value means less distortion, which is desirable for stable operations.

Case Study: Application in Lithium Production

A case study from Qinghai Jintai Lithium Industry showcases the application of bipolar membranes in the production of lithium carbonate. The process involves electrolyzing the tail liquid, a high-concentration sodium chloride solution originating from the lithium-sodium separation section of the salt lake brine production to produce acid and alkali for reuse within the production line. This not only ensures a stable supply of necessary chemicals but also contributes to environmental sustainability by minimizing waste.

In the context of lithium production, the ability to produce acid and alkali on-site is particularly valuable. Transporting these chemicals to high-altitude areas like Tibet can be challenging and expensive. The bipolar membrane system provides a localized solution that reduces dependence on external supplies and simplifies logistics.

Process Advantages in the Jintai Case

- Automation: The high level of automation simplifies operations, making the process accessible even to those unfamiliar with ion exchange operations.

- No Wastewater Production: The system's design ensures that acid and alkali are produced continuously without generating wastewater.

- Stable Concentration: The acid and alkali produced are of a stable concentration, suitable for direct use in resin analysis, eliminating the need for dilution. The concentration of hydrochloric acid and liquid alkali discharged can be stably maintained at 12%, with high current efficiency, and the total power consumption per ton of alkali and acid can be controlled at 2600 kWh and below.

The concentration of the produced acid and alkali is crucial for their use in various industrial processes. A stable concentration means that the output is predictable and reliable, which is essential for processes that require precise chemical inputs.

Jintai Lithium Industry Bipolar Membrane Device

This Sunresin's electrodialysis system is engineered to produce acid and alkali at a consistent concentration of approximately 2mol/L. This precise concentration is ideal for resin regeneration, ensuring reliable and accurate results. Furthermore, the system is designed to integrate seamlessly with our proprietary mother liquor recovery resin system. This integration facilitates the efficient recovery of mother liquor from heavy carp, exemplifying our commitment to providing solutions that are both effective and environmentally conscious. The consistency in production negates the need for dilution, streamlining the process and maintaining the integrity of the output for direct application in various industrial processes.

In summary, bipolar membrane electrodialysis is a sophisticated yet user-friendly technology that offers significant advantages in terms of efficiency, environmental impact, and ease of use. Its application in industries such as lithium production demonstrates its potential to revolutionize traditional ion exchange processes.

Engage with Sunresin for Cutting-Edge Solutions

Are you looking to enhance the efficiency and sustainability of your industrial processes? Connect with Sunresin to explore how our advanced bipolar membrane electrodialysis technology can revolutionize your operations. Our systems deliver consistent, high-quality acid and alkali production, integrate seamlessly with sophisticated recovery systems, and are backed by our commitment to environmental stewardship and innovation. Take the first step towards optimizing your processes by contacting us today. Experience the power of precision engineering and dedicated customer service with Sunresin, driving innovation in ion exchange technology.

Sunresin, driving the innovation.

Free Quote

Resources

Adsorbent Resin

Bio-Pharmaceutical & Life Science

Enzyme Carriers

Hydrometallurgy & Mining

Chelating Resin

Chemical Industry

Chromatographic Media

Wastewater Treatment&Reuse

Food & Beverage Industries

Ion Exchange Resin

Civil & Industry Water Treatment

Equipments And Projects

Plant Extraction

Catalyst Resin

Solid Phase Peptide Synthesis

Product

Application

Contact Us

Sunresin Park,No.135, jinye Road, Xi’an Hi-tech Industrial Development Zone, Shaanxi-710076, China

seplite@sunresin.com

seplite_europe@sunresin.com

+86-29-89182091

Our Product List

Latest News

30

2024 08

Sunresin Makes Hurun China Top 500 List

The Hurun Research Institute recently released their "2023 Hurun China Top 500" list, with Sunresin has making the list in recognition of its outstanding market performance and innovation capabilities. This is the only company on the list in China's adsorption separation materials industry.

22

2024 06

Exhibition Highlights | Sunresin Showcases at SIWW 2024 Singapore International Water Week

From June 19-21, 2024, the Singapore International Water Week (SIWW Water Expo 2024) was held at the Marina Bay Sands Expo and Convention Centre in Singapore. Sunresin showcased its internationally leading products and technologies at the event.

10

2024 05

Sunresin and Latin America: Ten thousand miles are still neighbors

In April, Ambassador Xu Yicong's book launch of "Family and Country Sentiments - Continuing Chapter" was successfully held in Beijing. The ambassadors of Latin America in China have come to congratulate Ambassador Xu, and Zhai Feng, Vice President of Bump Cycle, attended to celebrate the event. Dr. Gao Yuejing, as the representative of the important guests, gave a speech and expressed her most sincere blessing to Ambassador Xu for the publication of his new book.

Leave a Message

Please send any questions you want to know, we will reply to you immediately.

Choose File

Submit