Application of Sunresin's High-efficiency Defluoridation Resin in The Treatment of Industrial and Municipal Fluorine-containing Wastewater

Discharging fluorine-containing wastewater that does not meet the standards can pose great harm to the natural environment, as fluoride ions can accumulate in soil and water, causing damage to the ecosystem. Excessive amounts of fluoride ions can have adverse effects on plant growth and cause toxicity to aquatic organisms, and in severe cases, may lead to ecological disasters. If there are not properly method to treat the fluoride ions, they could enter water body and then result in adverse effects on human health. Especially for People who are exposed to fluorine-containing wastewater over a long period of time are more susceptible to diseases such as osteoporosis and dental problems, and more severe cases can lead to damage to the nervous system and even endanger life.

Therefore, it is vital to implement strict control and management measures to protect the environment and human health from the harmful effects of fluorine-containing wastewater.

A Brief Introduction to Fluorine-containing Wastewater Treatment Technologies:

Industrial wastewater has over hundred ppm fluorine contained, the general treatment would be using calcium ion to generate precipitation and then filter out. However, there are still around 20 ppm of fluoride ions in the wastewater that cannot be precipitated, making it difficult for the wastewater to meet discharge standards, which would result in significant production and operation pressure for enterprise.

Industrial fluoride removal has several methods, which include: coagulation and sedimentation, adsorption, reverse osmosis, electrochemical methods, and ion exchange. These methods all have certain fluoride removal effects but also have their own advantages and disadvantages.

Coagulation and sedimentation:

The most common way is lime or carbide slag precipitation is generally used, using calcium ions in the lime to generate calcium fluoride precipitation to remove fluoride ions.

Advantages: Simple principle, convenient treatment, low cost, and good effect. It is currently widely used in the treatment of high-concentration fluoride water.

Disadvantages: It produces a large amount of sludge, and the fluoride removal accuracy cannot reach the discharge standard, requiring secondary treatment.

Adsorption:

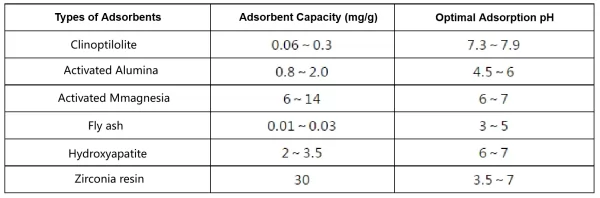

The commonly used adsorbents for fluoride removal are activated alumina, zeolite, and activated magnesia, which are used to adding into water body to to remove fluoride ions.

Advantages: The method has the capability to reduce the fluoride concentration in industrial wastewater from 10 mg/L to below 1 mg/L, with a high level of treatment accuracy.

Disadvantages: However, this method has low adsorption capacity and is prone to drain away during treatment process, resulting in a higher cost of defluorination and the mixing of a large amount of impurities into the wastewater.

Reverse osmosis:

By applying high pressure to change the natural osmotic direction, water molecules in high fluoride water are pushed towards the low-concentration solution side of the semi-permeable membrane to filter out fluoride ions and reduce the fluoride content in the water.

Advantages: Simple operation, no need to add chemical reagents, high treatment efficiency.

Disadvantages: The process of fluoride removal has no pertinence, high TDS content in the water will greatly shorten the service life, high equipment cost, high energy consumption, and requires a large amount of space.

Ion Exchange Method:

The ion exchange method involves modifying ordinary resins to create resins with functional groups that can perform ion exchange in a solution. This method can effectively remove fluoride ions from water by using ion exchange resins.

Advantages: Simple operation, long service life, and applicable to various type of fluoride-containing wastewater, with a wide range of applications.

Disadvantages: Not suitable for direct treatment of high-fluoride wastewater.

In summary, different fluoride removal methods have their own advantages and disadvantages, and it is necessary to choose a suitable method for treatment according to the actual situation. In practical applications, the selection of fluoride removal methods is usually based on factors such as the characteristics of wastewater, treatment requirements, and economic costs. For the treatment of high fluoride wastewater, the combination of chemical precipitation and ion exchange method is the most effective, with characteristics of high efficiency, low energy consumption, and high accuracy. For low fluoride wastewater, direct use of ion exchange method has significant advantages.

Sunresin's Fluoride Removal Resin Mechanism and Characteristics:

To meet the high requirements of enterprises for fluoride content in wastewater and residents' demand for fluoride-free drinking water, Sunresin's research team has continuously researched, developed, and improved targeted adsorption fluoride removal resins LSC-760 and LSC-860 based on the typical industry wastewater quality and treatment process characteristics. Both resins have high selectivity for fluoride in water, with LSC-760 being an activated alumina modified resin and LSC-860 being an activated zirconium modified resin. Currently, these two resins have been applied in the treatment of fluoride-containing wastewater in multiple fields, providing customers with high-quality and efficient fluoride removal solutions. These resins not only effectively reduce fluoride emissions but also reduce environmental pollution and human health hazards, with important environmental and social significance.

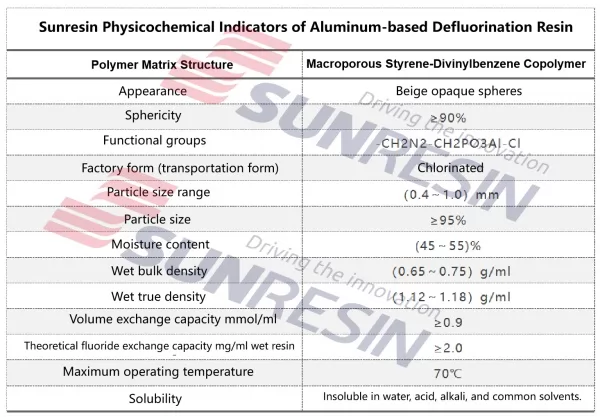

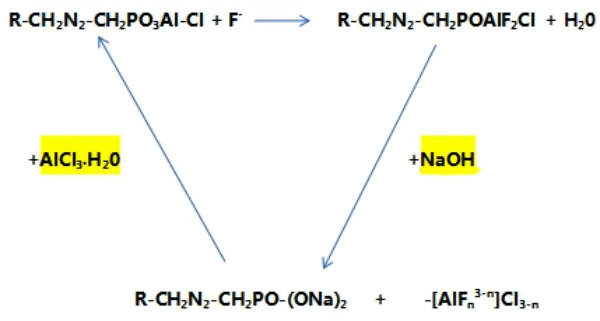

Ordinary ion exchange resins have limited fluoride removal efficiency mainly due to the low selectivity of the resin towards fluoride ions (SO42->NO3->CL->OH-> F->HCO3 ->HSiO3-)."LSC-760 is a special large-pore modified resin developed by Sunresin for removing fluoride ions from water. The resin is modified by chelation by loading Al3+ onto the resin skeleton to obtain a new type of fluoride removal resin.

Adsorption mechanism: Since Al3+ has an octahedral coordination field, after loading onto the resin, it will form an unsaturated complex with remaining coordination points binding with water. When it comes into contact with high fluoride water, due to the stronger coordination ability between F- and Al3+, [AlFn3-n] fluorine-aluminum complexes (n=1-6) can be formed, replacing the water and causing ligand exchange adsorption to fix F- and achieve solid-liquid separation of fluoride removal from water. The complexes formed by F- and Al3+ are more stable than those formed by other common ions in water, so a prominent feature of this method is its high selectivity for fluoride removal and stable fluoride removal effect, making it a suitable method for adsorbing fluoride ions.

Characteristics of Sunresin Special Resin for removing fluoride ions:

SEPLITE® LSC 760 Chelating Ion Exchange Resin produced by Sunresin is a resin material specifically designed to remove fluoride ions from water, with the following main characteristics:

Strong selectivity: The resin has a high selectivity for fluoride ions, which can effectively adsorb and remove fluoride ions from water, while having low adsorption capacity for other anions and cations.

Large adsorption capacity: This resin has a high adsorption capacity and can treat a large amount of fluoride-containing wastewater. Even after long-term use, it can still maintain a high adsorption efficiency and has a long service life.

Strong resistance to pollution: The resin has a special structure and functional groups, which are not easily contaminated by pollutants. The resin has high strength and will not experience phenomena such as increased pressure drop or decreased adsorption efficiency during use, and can maintain a stable adsorption efficiency.

Strong regenerability: The resin can recover its adsorption performance by reloading activated alumina, which avoids environmental pollution and resource waste caused by abandonment.

Introduction to Sunresin Special Resin for removing fluoride ions:

SEPLITE® LSC760 Chelating Ion Exchange Resin has the characteristics of strong selectivity, high adsorption capacity, strong resistance to pollution, strong regenerability, and easy operation, making it an ideal material for removing fluoride ions from water. Currently, this resin has been successfully applied in the field of fluoride-containing wastewater treatment, including mine water, comprehensive utilization of electronic industry wastewater, and achieving standard discharge of municipal sewage. Therefore, Sunresin's fluoride removal resin is an indispensable key element in adsorption processes, and its efficient fluoride removal capability and excellent adsorption performance make it the preferred choice for many customers.

Wastewater Fluoride Removal Experiment Case:

Experiment Name: Wastewater Fluoride Removal Experiment

Raw Material Description: The raw material is a colorless and transparent liquid with an F- ion concentration of 10.03ppm, neutral pH, and a conductivity of 4.5mS/cm.

Resin Used: SEPLITE® LSC760

LSC-760 resin has the ability to remove fluoride ions to a level below 1ppm, as shown in the following chart. This resin has a high fluoride removal efficiency in the pH range of neutral to alkaline, and is easy to regenerate. After multiple verifications of fluoride removal from industrial wastewater, it can meet the requirements of enterprises for standard discharge of fluoride-containing wastewater.

_1698304772_WNo_600d383.webp)

In the future, Sunresin will continue to devote itself to the research and development of high-quality and high-efficiency fluoride removal resin products, making greater contributions to environmental protection.

Case Study: Sunresin Defluorination Resin in Industrial Applications

Case 1: Integrated Wastewater Treatment Project in an Electroplating Industrial Park in Huizhou

Wastewater discharge: 1000m3/d, fluoride concentration around 10ppm; effluent fluoride concentration < 1ppm.

Case 2: Mine Water Treatment Project in a Construction Group Co., Ltd.

Wastewater discharge: 3000m3/d, fluoride concentration around 3ppm; effluent fluoride concentration < 1ppm.

Case 3: Defluorination Project in a Company in Hangzhou

Effluent flow rate: 50,000t/d, using 200m³ of Sunresin's defluorination resin to reduce fluoride concentration from 1.5ppm to within 1ppm.

Case 4: Mine Water Treatment Project by an Environmental Protection Company

Wastewater discharge: 4000m3/d, fluoride concentration around 5ppm; effluent fluoride concentration < 1ppm, with stable operation.