Color Indicator Resin Allows You to Understand the Exhaustion State of The Resin Timely

Color indicator resin allows you to understand the exhaustion state of the resin timely

The color indicator resin is introduced into gel type anion or cation exchange resin through a special process, which makes the color changes under different ion types. It is convenient for users to judge the exhaustion state of ion exchange resin directly.

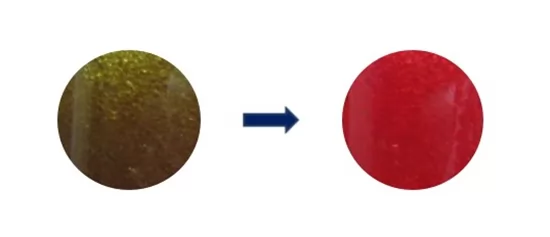

The shipping form of the color indicator cation resin is H form. The initial appearance of H form cation is yellow-green, when the resin contacts with Ca2+ and Mg2+ ions in water, the Ca2+, Mg2+ and other ions will exchange with H+ ions on the resin, and bind to the molecular matrix of the resin, while H+ ions drop out to the water phase. At this time, due to the loss of H+ ions

from the functional group of the resin, the color of the exhausted cation resin changes from yellow-green to rose red with the help of indicator. After regeneration with acid, the H+ ions in the acid will replace Ca2+, Mg2+ ions etc. and back to the resin. The H+ resin returns to its initial yellow-green color state.

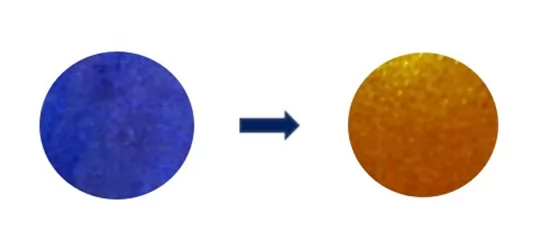

The shipping form of the color indicator anion resin is OH form. The initial appearance of OH form anion is dark blue, when the resin contacts with HCO3-, HSiO3-, CO32- and other ions in water, these ions will bind to the molecular matrix of the resin, while OH- ions drop out to the water phase. At this time, due to the loss of OH- ions from the functional group of the resin, the color of the exhausted anion resin changes from dark blue to light yellow with the help of indicator. After regeneration, the OH- ions in the alkali will replace the ions such as HCO3-, HSiO3-, and CO32- which are bind on the resin, and the resin returns to its initial OH- form in the color of dark blue.

Main applications of color indicator resin:

(1) Used as mixed bed resin

The colored anion and cation exchange resin can be pre-mixed in a certain proportion as the mixed bed resin. Compared with the conventional mixed bed resin, it enhances the user's intuitive judgment of the resin exhaustion state, facilitates the user to timely regenerate the resin, ensures the water treatment performance of the system and quality of the effluent.

Key products:

Seplite® MB10IND/MB20IND/MB30IND

(2) It is used as indicator with hydrogen conductivity meter to detect steam water parameters in thermal power plant.

The color indicator cation resin is an intuitive and effective supplement to the on-line detection instrument of steam water circulation system in thermal power plant. The resin column is installed before the hydrogen conductivity meter. When the water pass through the ion exchange column, the free ammonia in the condensate water can be removed, and all cations in the water can be converted into hydrogen ions with higher conductivity, which greatly improves the monitoring sensitivity of the instrument to the ions in the water; at the same time, the apparent color changing when resin exhausted also facilitates the operator to understand the exhaustion state of the resin in time, make correct judgments on the water quality, and improve the safety of the plant operations.

Key products: SC130H IND