Efficiency Desalting Process in the Production of Ectoine

Ectoine: A multi-functional, highly sought-after ingredient in skincare, and a "rising star" in the field of ingredients. It is a new favorite in the world of skincare. Its production also demonstrates the new application of synthetic biology technologies!

Ecotoine——the all-rounder in skin care:

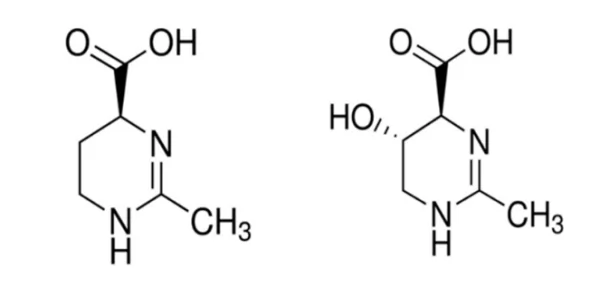

Ectoine (tetrahydropyrimidine) is a compatible water molecule-binding solute (osmoprotectant) produced by several bacteria under osmotic stress and adverse environmental conditions. This amino acid derivative can accumulate in cells at high concentrations without interfering with natural processes and can protect cells from radiation or osmotic stress.

Microbial fermentation is a cutting-edge technology for cosmetics. Microbial fermentation technology has become a "tool" for more and more brands to develop their markets. Ectoine and bifidus ferment product lysate, hyaluronic acid, galactose-like yeast ferment product filtrate (Pitera®) and other popular "miracle skin care ingredients" are all derived from "fermentation", and they are all international and domestic best-selling high-end skin care ingredients, and are also one of the new processes developed through synthetic biology technology.

The desalting process of Ecdoine:

Ectoine itself a hydrochloride salt compound, is susceptible to a decrease in quality and efficacy due to the presence of salt, particularly in large-scale production. Therefore, the desalination process plays a critical role in the preparation of Ectoine. The desalination process for Ectoine usually involves the use of ion exchange, reverse osmosis, and electrodialysis to gradually separate the salt from Ectoine, thereby achieving the goal of improving its purity and efficacy.

Ion Exchange Desalination:

Ecdoine desalination processes are usually carried out with ion exchange resins. Specifically, this process usually uses ion exchange resins with specific functions, such as strongly acidic cation exchange resins, weakly acidic cation exchange resins, etc.

The advantages of using conventional ion exchange resins for Ecdoine desalination in a low salt environment include simplicity of operation, ease of control of the process, high desalination efficiency, reusability, etc.

Reverse Osmosis Technology:

Reverse osmosis is the process of separating and removing water and other substances using reverse osmosis membranes to remove ions, solutes, other organic substances, etc. from it.

Electrodialysis:

The separation and removal of ions is carried out by using the characteristic of different migration rates of electrolytes in the electric field. Ions outside the charge of the molecule will gather near the electrode that has the reverse charge, and then the counter ions are released on the surface of the electrode, and such a repeated cycle can separate the organic matter in the electrolyte and get the result of desalination.

At the same time, there are some disadvantages of electrodialysis desalination, such as the electrodes are easily deactivated in use and need to be replaced regularly. Moreover, the reproducibility of electrolytic desalination is not as good as some chromatographic desalination processes. For samples with high salt content, the desalination process needs to be repeated through several cycles, which increases the operation time and cost, and may reduce the efficiency and sensitivity of the analytical process.

Uniform particle chromatographic desalination process in high salt environment:

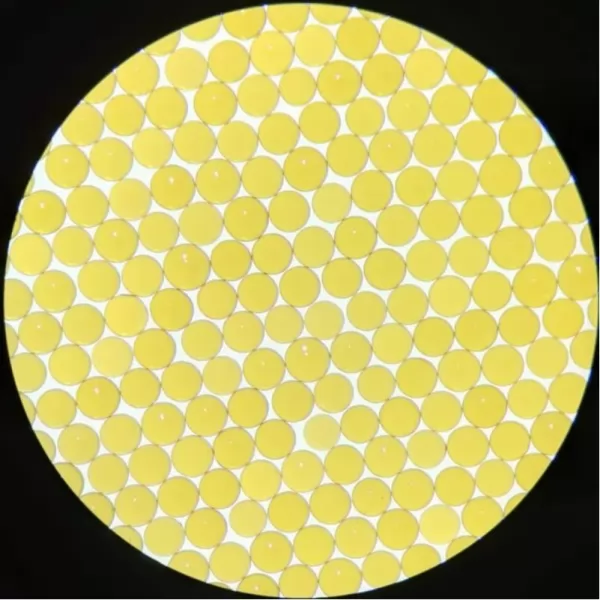

In the face of high salt environments, due to the limited adsorption capacity of conventional ion exchange resins, uniform particle chromatographic desalination resins were turned to purify Ecdoine from complex mixtures.

The uniform particle ion exchange resin independently developed by Sunresin is used in the desalination and purification process of Ecdoine. Under the high salt system environment, the inorganic/organic salt removal rate is up to 90% or more. Compared with the conventional desalination resin , the uniform particle characteristic of the resin makes the material more uniformly distributed in the column and the flow is smaller, thus making the desalination effect more excellent, significantly improving the production efficiency of the subsequent process and reducing the production cost.

Chromatographic Desalination Euipment Applications:

In addition, in response to the current high salt problem prevailing in fermentation broth, Sunresin has developed SSMB continuous chromatographic salt separation process and continuous ion exchange process by combining the characteristics of the broth.

SSMB (sequential simulated moving bed) continuous chromatography process: the fermentation hydrolysate containing high salt and pigment is separated from sugar and salt through customized chromatography resin and system, using the ion repulsion mechanism of chromatography resin, the whole process only requires pure water, without any acid and alkali consumption, and can achieve the removal of more than 90% of ash and part of pigment, which can significantly reduce the load of the subsequent ion exchange system, reduce the consuming amount of resin, and thus reduce the consumption of regeneration chemicals.

The advantages and features of Sunresin's SMB (simulated moving bed) chromatography equipment are as follows:

1.Suitable for large scale batch product separation

2.High precision, high yield and low water consumption

3.High versatility of equipment, one set of equipment can realize different product separations, and also can selectively add tube ports to realize 2-3 different component separations according to customer requirements.