Exceed Standard Drinking Water Treatment Resin and High Efficiency Processing System

Exceed standard drinking water treatment resin and high efficiency processing system

Water is indispensable for the survival of human beings, and the channels to obtain water from nature are various, such as desalinated seawater, groundwater, surface water (rivers, lakes). But regardless of the source, for the sake of human survival and health, we have strict regulations and restrictions on the indicators of domestic water. However, the differences in geological composition and environmental conditions in different parts of the natural world can lead to differences in the ion content of different water sources and often lead to exceedances of water quality standards. In order to make better use of water sources for human beings, it is necessary to remove the excessive ions in the water with high efficiency and precision, so as to reach the safety water quality standard.

According to the demand of this field, Sunresin has organized a professional R&D team. After repeated experiments, pilot tests and large-scale verification, Sunresin has developed a series of special resins for water treatment that exceed the standard. It can specifically and accurately remove the excessive boron, fluorine, nitrate and chlorate in the water source, so as to achieve the continuous compliance with water quality standards.

Part of resins products for excess drinking water:

(1) Special boron removal resin:

Seplite®LSC780 boron removal resin that exceed the standard can achieve high selective adsorption and removal precision of boron can reach PPB level or even PPT level (electronic industry). The resin has the characteristics of large adsorption capacity and simple regeneration, and is commonly used in industrial water treatment fields such as seawater desalination engineering, municipal drinking water engineering, ultra-pure water in electronic industry and other industrial water treatment fields.

(2) Nitrate removal special resin:

Seplite®LSI106plus nitrate removal resin for removing nitrate is used for adsorption and removal of nitrate. With high selectivity, it is not easily affected by the competition of other anions in water. The removal accuracy of nitrate nitrogen can reach below 1ppm and often used in municipal water treatment projects.

(3) Perchlorate removal resin:

Seplite®LSI106 perchlorate removal special effect resin has good selective adsorption to perchloric acid root in the water, the exchange adsorption capacity is large, the treated effluent index is stable. It is often used to remove residual chlorine after disinfection in waterworks.

(4) High efficiency fluoride removal resin:

Seplite®LSC760 Fluorine Removal Specialty Resins are New Nanoscale Metal-Loaded Polymer Resins. The resin has a single selectivity for fluoride ions in the aqueous phase. Compared with the conventional anion exchange resin, the resin has high selectivity, large capacity, high processing precision, less dosage of resin under the same working condition and long service life (generally more than 3 years); The fluorine content of effluent can be maintained below 1ppm.

At the same time, Sunresin fully takes into account the characteristics of super standard water, such as low content of super standard factors, large treated water volume and long adsorption time, and innovatively applies Puritech®multi-channel valve system technology to the resin adsorption treatment process of super standard water, avoiding the problems of large resin dosage, large investment in system equipment and large consumption of reagents in traditional fixed bed system due to low resin utilization, taking into account the contradiction between large water volume and long cycle time, saving investment cost and reducing operation cost to the greatest extent.

Puritech®multi-channel valve technology is an advanced and mature high-efficient resin treatment system. In the scale operation of various related industrial fields abroad, the system has shown its remarkable advantages in use efficiency and reagent consumption. In the field of drinking water treatment in the UK, multi-channel valve system of Puritech has a very wide range of industrial applications for nitrate removal with high treatment efficiency, stable treatment indexes and reliable operation.

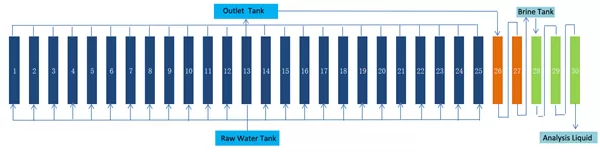

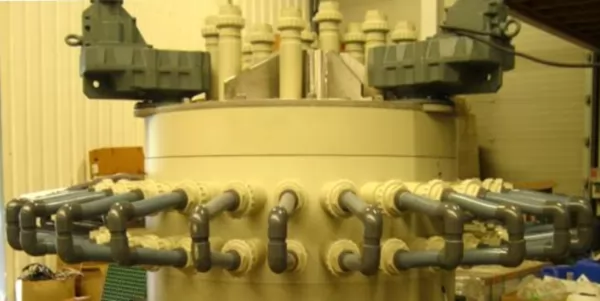

Puritech®multi-channel valve system adopts multiple resin columns to operate in parallel, and different functional areas are divided according to the process requirements. Different functional areas operate independently at different times according to the program. During the operation of the system, the resin column remain stationary, and through the internal precision switching of the Puritech®multi-way valve system with global patent technology, the different liquid pipelines are switched to different resin columns to complete the switching of resin function zones, with no idle resin and no idle time during the whole operation process. Utilization rate, less resin dosage, less reagent consumption and less wastewater discharge at the same treatment scale.

Technical advantages of Puritech®multiple-way valve system:

(1) The use and operation efficiency of resin is higher:

Puritech®multi-channel valve system divides multiple resin columns into different working areas, which is different from the resin waiting caused by the process of adsorption, washing, analysis, washing and regeneration of a single resin column bed in the traditional fixed bed mode. Under the control of the set program, the system can realize the switching and continuous operation of different functions of the resin column bed (different resin columns are in the corresponding process at the same time). The operation efficiency of resin is greatly improved.

(2) Less resin content and lower investment cost:

Puritech®multi-channel valve system converts a large resin column into multiple small resin columns for orderly and efficient operation, which significantly improves the utilization ratio of resin. Compared with the traditional fixed bed system, the resin dosage can be reduced by 100-300% in the same treatment scale.

(3) Less reagent consumption and lower operating cost:

As the analytical agent with a similar equivalent ratio is adopted, the amount of analytical agent used in the process of resin analysis can be greatly reduced (compared with the traditional fixed bed system, the amount of analytical agent can be reduced by 100%), and the corresponding amount of wastewater is also significantly reduced, which reduces the system treatment, operation cost and environmental pressure.

(4) Simplified process pipeline and simpler operation:

Puritech®multi-way valve system can simplify complex on-site pipelines and realize simple and orderly operation of complex processes.

(5) Intelligent system control and more convenient operation:

The system adopts fully intelligent control, convenient and simple man-machine dialogue interface, flexible and open operation mode, which improves the humanization and simplicity of system operation.

(6) Automatic control and data recording system to ensure stable processing effect of the system:

The operation process is executed automatically and accurately by the system to avoid the influence of human factors to the greatest extent. At the same time, the system provides a perfect operation data record preservation, which is easy to summarize, organize and trace the data.