High Efficient Treatment of VOCs in the Waste Gas of Chlorinated Hydrocarbons

Dichloromethane, dichloroethane, chloroform and other chlorinated hydrocarbons are often used as solvents or synthetic raw materials in pharmaceuticals, pesticide, fine chemical industry and other industrial production fields. However, due to the low boiling point of dichloromethane, dichloroethane and other chlorinated hydrocarbons, obvious volatilization will occur in the process of production and use, which will bring economic loss caused by material loss to the enterprise, as well as environmental protection pressure to the waste gas treatment and eligible emission of the workshop.

For the treatment of VOCs in chlorinated hydrocarbon waste gas, because the adsorption selectivity of activated carbon (carbon fiber) to chlorinated hydrocarbon molecules is not high, if in conventional activated carbon (carbon fiber) adsorption mode, the adsorption and removal recovery rate is low and there is fluctuation, and the gas export is difficult to reach the standard stably; at the same time, the replacement frequency of activated carbon (carbon fiber) is high. It will produce more hazardous wastes to be treated, which will bring extra burden to the enterprises. Therefore, using activated carbon (carbon fiber) adsorption to treat chlorinated hydrocarbon waste gas is not an efficient choice. At present, RTO incineration technology, which is widely used in the treatment of VOCs in waste gas, is also limited to be applied in the treatment of VOCs in chlorinated hydrocarbon waste gas by the problems of corrosive hydrochloric acid gas and dioxin carcinogens produced in the combustion of chlorinated hydrocarbon, etc. (At present, RTO incineration technology can only deal with the waste gas with the content of chlorinated hydrocarbon less than 200mg /m3).

In the face of the industry problem of the treatment of chlorinated hydrocarbon waste gas, Sunresin creatively introduces resin adsorption technology to the treatment of chlorinated hydrocarbon waste gas. Using the high selective adsorption between the special resin skeleton molecule and the chlorinated hydrocarbon molecule, combined with the complex pore structure design inside the resin, it realizes the efficient adsorption and interception of chlorinated hydrocarbon molecule in the waste gas, and carries out resource recovery. Industry verification shows that the recovery rate of adsorption and removal of chlorinated hydrocarbon molecules by Sunresin's special resin and supporting treatment device of waste gas treatment is over 99%, and the export is stable and up to standard. The products and technologies of waste gas treatment resin have been widely recognized by relevant enterprises.

Advantages of Sunresin's special resins and technologies for thetreatment of chlorinated hydrocarbon waste gas:

1) The efficiency, accuracy and working load are high. The recovery rate of adsorption and removal of chlorinated hydrocarbon molecules is over 99%;

2) Resin is a regular spherical particle with certain structural strength, which has smaller wind resistance and lower energy consumption compared with activated carbon (carbon fiber) system;

3) The treatment index is stable, the resin loss is small, and the service life is long (more than five years under normal conditions, the annual supplement rate is less than 10%);

4) The treatment cost is significantly lower than that of activated carbon (carbon fiber) adsorption recovery process;

5) The treatment has great flexibility and can withstand large air volume and concentration fluctuation.

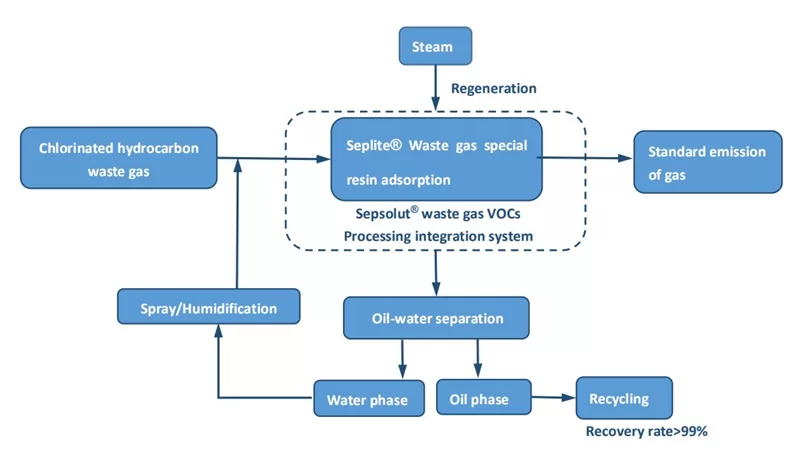

Chlorinated Hydrocarbons waste gas resin adsorption treatment technology flow chart:

Project case:

Dichloroethane waste gas treatment project of a chemical enterprise

Dichloromethane waste gas treatment project of a pharmaceutical enterprise