Make the Treatment of VOCs Safer, More Efficient and More Economical

Make the treatment of VOCs safer, more efficient and more economical

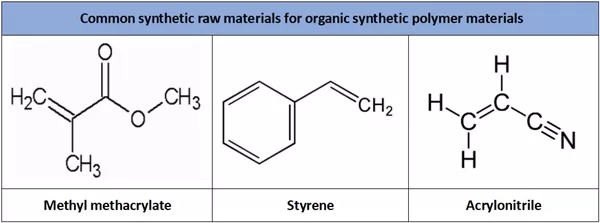

Organic synthetic polymer material is a kind of polymer material with certain functional properties, which is produced by the polymerization of unsaturated organic molecules with double bond structure under initiating conditions. Due to its good strength performance, excellent chemical corrosion resistance and lightweight, it has been widely used in all aspects of our production and life. However, in the process of chemical synthesis and production of organic synthetic polymer materials, the commonly used raw materials such as acrylic, acrylonitrile, styrene and other organic monomer molecules have certain volatility. Even if condensation reflux process is adopted for intercept recycling, some VOCs will inevitably escape to the waste gas. If not effectively treated, the air will be polluted and valuable resources will be wasted.

At present, the feasible treatment methods for this problem are mainly the combustion method and the adsorption method. The combustion process achieves the target by forced burning volatile gases. The heat generated by combustion can be recovered, but organic molecules such as acrylates and styrene have a low heat value but with a high value for product itself. If they are simply processed by combustion, it is not economical. The adsorption process uses core adsorption materials to effectively adsorb and intercept VOCs molecules to achieve the purpose of waste gas treatment. However, traditional activated carbon, molecular sieve and other adsorption materials, due to the lack of purity in the surface and pore structure (containing impurities such as metals), will cause the adsorbed unsaturated organic molecules to rapidly polymerize in the pores of the adsorbing material to form polymers and block the pores, which affects the subsequent adsorption processing performance, and the polymers formed in the pores are difficult to effectively remove, resulting in the failure of periodical use of adsorption materials, as well as short life and high processing costs. Moreover, the polymerization reaction of organic molecules is an exothermic reaction, once the adsorbed unsaturated organic molecules polymerize in the pores of the adsorption material, the instantaneous heat energy generated in the limited space will also bring certain safety hazards (especially for activated carbon).

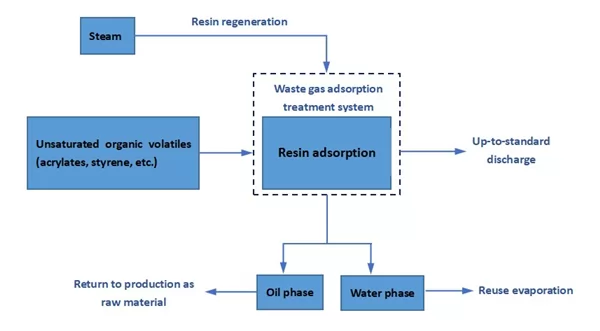

The special resin seplite® CT-10 for VOCs treatment developed and produced by Sunresin, adopts a special synthesis process and production control, so that it has a higher active specific surface area, good mechanical strength and thermal stability, with better pore structure and higher purity. In the adsorption treatment of unsaturated VOCs, the good purity and inert environment inside the seplite® CT-10 resin structure can effectively avoid the occurrence of the polymerization of adsorbed VOCs, which fundamentally eliminates the problem of molecular curing and exotherm caused by the polymerization of unsaturated organic molecules, avoids damage to the resin adsorption material, and significantly reduces the potential safety hazards caused by polymerization exotherm. The adsorbed saturated resin can be effectively regenerated by high-pressure steam purging, and the regenerated unsaturated organic molecules can be recycled back to the production process, reducing the costs. After simple cooling treatment, the resin after steam regeneration can enter into the next cycle of adsorption. With periodical cycle, the resin will have long service life and lower operation cost.

VOCs treatment equipment

Seplite® CT-10 resin processing route of VOCs treatment:

Aiming at the unsaturated VOCs produced in the chemical synthesis of organic synthetic polymer materials, Sunresin has high-performance recyclable core adsorption materials and corresponding supporting process solutions, with which the core adsorption material and process can be optimized based on user's specific working conditions to create more values for users while solving the environmental problems. Our professionality will definitely meet your needs!