Purification of Condensed Water in Evaporated Salt Treatment of High Salt Organic Wastewater

In the chemical production, especially in the fine chemical industry such as pesticide, medicine, dye, etc., due to the large use of acid, alkali, organic solvent and reagent in the production, the produced wastewater often contains high salt content and organic matters, which usually needs evaporating salt treatment to separate the salt and water in the wastewater, so as to realize the desalination of the wastewater. However, in the process of salt evaporation, some organic matters in the wastewater which are azeotropic with water will enter into the condensate with the evaporation of water, resulting in the COD of condensate exceeding the standard and accompanied by color, which cannot be discharged or reused. Only after further coefficient improving, can the condensate be discharged to the standard or recycled.

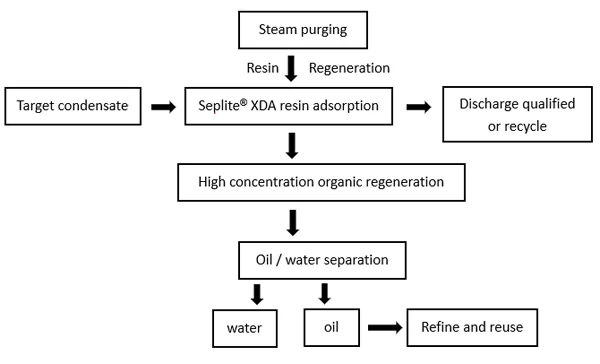

Focusing on the non-polar or weak polar organic molecules which are usually azeotropic with water in the wastewater of pharmaceutical and chemical industry, Sunresin adopts Seplite® XDA series high specific surface macroporous adsorption resin specially developed to remove the non-polar or weak polar organic molecules in the condensate with high precision, reduce COD and chroma, and realize the discharge and reuse of the condensate meeting the standard. The resin with saturated adsorption can be regenerated by steam purging, and the organics in the regeneration liquid can be refined and recovered, so as to reduce the production cost.

Process flow of COD excessive condensate extraction treatment with Seplite® XDA series resin

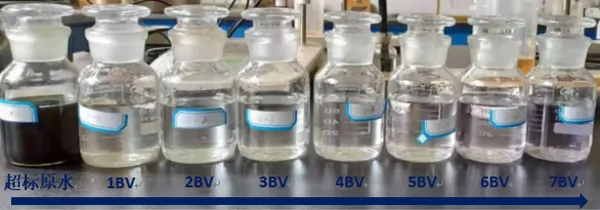

Adsorption, COD reduction and decolorization effect of Seplite® XDA series resins

Advantages and characteristics of Seplite® XDA series resin in the treatment of COD excess condensate

(1) Resin treatment capacity is large, regeneration is easy, treatment cost is low, and regeneration process will not introduce other reagents and produce secondary pollution.

(2) The treatment process is simple and reliable, with low requirements for system equipment and personnel operation, and easy to master.

(3) Low investment and less land occupation.

(4) The good impact resistance and pollution resistance of the resin make the system have a certain buffer capacity, even if the front-end evaporation equipment fails or the process is adjusted, the effluent quality can still be guaranteed.