Seplife® UNI Series Solid Phase Carrier, New Choice for Peptide Synthesis

Polypeptide is a kind of compound which is made up of many amino acids connected by peptide bond. It is usually composed of 2-100 amino acid molecules. It has biological activity and can participate in and regulate the functional activities of organs, tissues and cells in the body. With the development of science and technology as well as the deepening of human understanding of polypeptide research, the high-specific biological activity of polypeptide molecules with different structures has been gradually recognized and applied. For example, peptide drugs are the preparation of peptides with specific amino acid sequence by artificial way, which can be used for the prevention and treatment of some diseases. How to get the amino acid sequence peptide we want has naturally become the core topic in the field of peptide research and production.

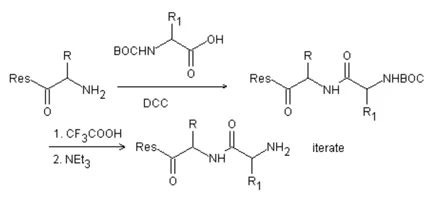

In 1963, a pioneering work of Merrifield, an American biochemist, overturned people's cognition of peptide synthesis. The technology of solid-phase peptide synthesis (SPPs) came out quietly, which had a profound impact on peptide synthesis. Solid phase peptide synthesis technology has become the mainstream technology in the field of peptide synthesis due to its advantages of good yield, high purity, stable quality and environmental friendliness. It has been widely used in the preparation of 3-50 amino acid sequence peptides.

With the development of solid-phase peptide synthesis technology, equipment, synthesis carrier and technology, there are more and more kinds of synthetic peptides, which benefit people's livelihood. The solid-phase synthesis of polypeptide mainly includes synthesis, peptide cutting, purification, concentration, freeze-drying, packaging and other technological processes. The selection of raw materials, reagents and technological control in each step will affect the yield and quality of polypeptide.

As the key raw material of peptide solid-phase synthesis, solid-phase carrier's swelling degree, substitution degree, particle size, residue, reaction site distribution and other key indicators will affect the yield and purity of peptide synthesis. The swelling degree, substitution degree and particle size of the carrier can be well controlled by adjusting the technological parameters of the carrier synthesis. However, at present, the distribution of carrier reaction sites is non-uniform. With the growth of peptide chain in the process of peptide synthesis, the growth space of peptides in the carrier is gradually reduced. The non-uniform distribution of reaction sites will bring local space hindrance to the growth of peptide chain, reduce the probability of contact reaction between amino acids and pre peptide chain, and increase the probability of missing peptide and inserted peptide of impurities, affecting yield. This is especially obvious on the synthesis of long-chain peptides.

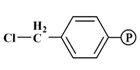

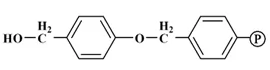

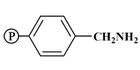

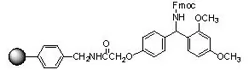

Sunresin, as the world's leading supplier of solid-phase synthesis carriers for peptides, has developed the Seplife® UNI series of solid-phase synthesis carriers with uniform reaction site distribution based on the traditional solid-phase carrier synthesis technology, aiming at the problem of space hindrance in the synthesis process. Under the premise of not changing the structure of the original carrier, the series of carriers can realize the uniform distribution of reaction sites in the carrier through special process control, improve the carrier space resistance in the process of peptide synthesis to the maximum extent, make the solid-phase synthesis of special difficult synthetic peptides and long-chain peptides easier, and the yield of medium and short-chain peptide synthesis unit carrier is higher.

-

Seplife® UNI series solid phase carrier

-

Seplife® UNI series solid phase carrier advantages

(1)It can effectively reduce the hindrance effect in the synthesis process.

(2)The distribution of functional sites is uniform, which can improve the contact rate of amino acids and pro peptides in long peptide synthesis.

(3)The reaction efficiency is high, the reaction time is shortened, and the racemic risk caused by prolonged reaction is reduced.

(4)The yield of peptide per unit carrier is higher.