Sunresin-Application of Adsorption and Separation Technology in Synthetic Biology

1. What is synthetic biology

Synthetic biology, known as the significant carrier of "third bio-technology revolution", is an emerging interdisciplinary field in the 21st century. Its essence is to make cells work for humans and produce desired substances. With this technology, many products that we encounter in our daily lives can be synthesized using biological methods.

Synthetic biology is a new interdisciplinary field that mainly focuses on the design, construction, and application of biological systems. It combines knowledge and methods from various fields such as engineering and biology, aiming to utilize existing biological mechanisms and technologies in nature such as biomolecules and biological reactions. By designing and constructing biological systems, and designing controllable gene regulatory networks, it achieves systematic biological regulation at the molecular level within cells.

2. Great Potential for Synthetic Biology in Achieving Carbon Neutrality

Synthetic biological manufacturing is a promising green production method, and with the global warming and the proposal of carbon neutrality in various countries, it has undoubtedly become one of the potential optimal solutions. Synthetic biological manufacturing can reduce energy and material consumption in industrial processes, and reduce waste emissions and air, water, and soil pollution, while significantly reducing production costs and enhancing industrial competitiveness.

In the context of global and national advocacy for "carbon neutrality," synthetic biology undoubtedly provides a very good solution. In 2014, the Organisation for Economic Co-operation and Development (OECD) released a report "New Policy Issues in Synthetic Biology," predicting that 35% of chemicals and other industrial products may involve biological manufacturing in the future.

The adsorption and separation technology that Sunresin is engaged in is a highly efficient separation and purification platform technology with strong environmental friendliness, high automation, and good operational accuracy. As a leading global company in the adsorption and separation technology industry, we have been actively considering how to integrate our more than 20 years of research and development accumulation and technological advantages in the field of adsorption and separation with the national carbon neutrality path to contribute to the achievement of the dual-carbon goals and help optimize and upgrade downstream application processes.

3. Application of Adsorption and Separation Technology in Synthetic Biology

During the production of synthetic biology products, the raw materials are transformed into the target product through microbial fermentation and are present in the fermentation broth. The key factor that restricts the production and application of synthetic biology products is the separation and purification of the target product.

Currently, in the separation and purification process, methods such as isoelectric point crystallization, ion exchange (fixed bed), and membrane separation are mainly used. However, these methods have problems such as low target product yield, high consumption of chemical reagents, large wastewater discharge, and significant environmental pollution.

Sunresin has developed a series of separation materials for the separation and purification of fermentation broth, and has developed application processes and system equipment for different use cases, providing customers with comprehensive solutions.

_1698303611_WNo_600d104.webp)

3.1 Desalination, decolorization, and deproteinization:

Ion exchange resins, which are a combination of cation and anion resins, are generally used to reduce the conductivity to the target level. Strong acid, weak acid, strong base, and weak base resins are used based on the properties of the material, such as acid and alkali stability, and resin retention.

Strong basic anion exchange resins or large pore adsorption resins are generally used for decolorization. They can also remove some proteins.

3.2 Adsorption of product and impurities:

Resins with specific functional groups can be used to selectively bind to target substances and impurities for removal. Large pore adsorption resins and ion exchange resins are generally used for adsorption, followed by solvent or acid-base analysis.

3.3 Chromatographic separation:

Ion exchange resins or large pore resins are used to adsorb the product and impurities, with certain capacity. The impurities are removed by gradient washing, and the product is analyzed with solvents or acid-base solutions at medium concentration. The resin is regenerated with solvents or acid-base solutions at high concentration.

3.4 Chromatographic separation:

3.4.1 Continuous chromatography SSMB for desalination, impurity removal, decolorization, and mother liquor recovery;

3.4.2 Medium-high pressure preparative chromatography.

4. Synthetic Biology Application of Butanedioic Acid

The downstream application of butanedioic acid is mainly in the synthesis of PBS and BDO. With the background of the "dual carbon" policy, biodegradable plastics are transitioning towards bio-based degradable plastics, opening up a future incremental market for bio-based PBS. Although there is already a huge existing market for BDO, the current production method does not align with the "dual carbon" concept.

Driven by downstream demand for the synthesis of PBS and BDO, there is enormous potential demand for butanedioic acid, especially for butanedioic acid produced through synthetic biology. The traditional chemical method of producing butanedioic acid has limited capacity expansion, and synthetic biology methods have already demonstrated cost advantages, making it a future development trend. Butanedioic acid will be produced through synthetic biology to meet the enormous downstream demand in the future.

Chemical Synthesis Method (I) of Butanedioic Acid

_1698303643_WNo_600d38.webp)

Chemical Synthesis Method I: Electrochemical Method, a method of synthesizing butanedioic acid through electrochemical redox reactions.

The main disadvantage is the high energy consumption, as well as factors such as policy restrictions, high equipment costs, and complex equipment operation, which limit its application in large-scale and industrial production.

Chemical Synthesis Method (II) of Butanedioic Acid

_1698303654_WNo_600d48.webp)

The hydrogenation reaction of maleic anhydride is the process of producing butanedioic acid by hydrogenating cis-butenedioic anhydride with hydrogen in the presence of a catalyst.

This reaction is carried out at a certain temperature and hydrogen pressure. The main limiting factors affecting the development of this process include excessive carbon emissions, yield of purity and ash impurities, and the selection of nickel or other precious metal catalysts.

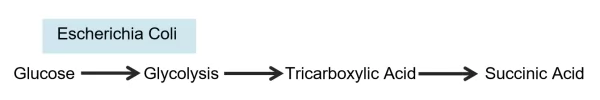

Synthetic Biological Process for Butanedioic Acid

The synthetic biological process of butanedioic acid is a green and environmentally friendly production method.

Using microbial strains for metabolic engineering of microorganisms such as yeast and E. coli, the process itself is sustainable and renewable, greatly reducing environmental pollution and providing a better solution for sustainable development.

In the biological synthesis process, the strains can be genetically modified and regulated, and even optimized for performance through artificial evolution in anaerobic environments, to select the optimal strain for producing the highest yield of butanedioic acid. This results in a product with higher purity and no chemical pollution.