Sunresin Condensate Polishing, Uniform Particle, Super Gel, Anion and Cation Exchange Resin

Sunresin Condensate Polishing, Uniform Particle, Super Gel, Anion and Cation Exchange Resin

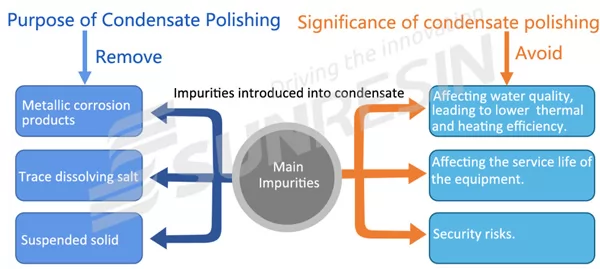

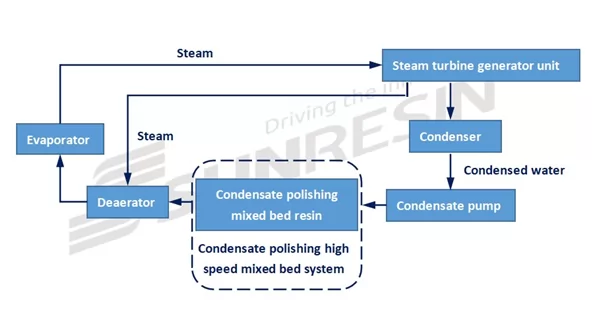

The condensed water generally refers to the steam generated by the boiler, which is cooled by circulating cooling water after the steam turbine works. As an important part of boiler make-up water, the quality of condensate will directly affect the operation efficiency, service life and safety of the system. During the operation of the system, the condensate will be polluted due to the corrosion of pipeline or equipment, a small amount of impurities brought into the boiler make-up water and other reasons. It is necessary to achieve the precision removal of a small amount of metal corrosives, micro dissolved salts, suspended substances and other impurities contained in the condensate, so as to ensure the quality of water supply and steam.

At present, the mature and widely used technology for condensate refining is condensate refining mixed bed resin treatment technology.

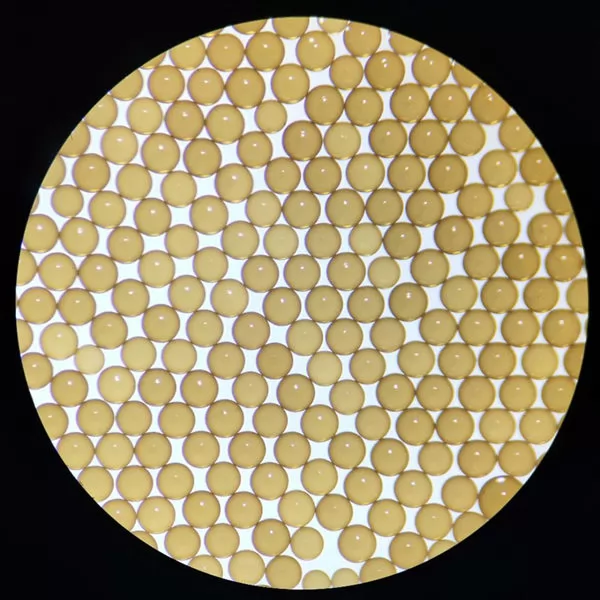

Aiming at the higher performance requirements of resin in condensate polishing process, Sunresin adopts the "spray granulation" technology to fill the gaps in domestic technology, and combines with the leading resin production line system in the world to produce the Seplite® Monojet™ SA8500CP uniform particle super gel, strong base anion exchange resinand the Seplite® Monojet™ SC7700CP uniform particle super gel, acid strength cation exchange resin, both of which are special for condensate polishing. They have high compressive strength, high sphericity after osmotic-attrition and grinding and high crosslinking, which greatly improve the treatment performance of condensed water. According to the experimental demonstration and authoritative testing and evaluation, the performance indexes of the above two kinds of monoplus have reached or exceeded the same type of monolus products in foreign countries.

Table 1. Comparison of performance indicators between Sunresin condensate refining resin and the same resin of a foreign brand

| Sample Designation | Same Resin of Other Brand |

Monojet™ SC7700CP |

Same Resin of Other Brand |

Monojet™ SA8500CP |

|

|---|---|---|---|---|---|

| Factory Type | H+type | H+type | OH-type | OH-type | |

| Volume Exchange Capacity (mmol/ml) | 2.24 | 2.26 | 1.22 | 1.21 | |

| Water Content (%) | 47.36 | 48.45 | 55.35 | 56.75 | |

| Average Granularity (μm) | 688.9 | 679.5 | 597.4 | 594.8 | |

| Evenness Ratio | 1.07 | 1.08 | 1.07 | 1.06 | |

| Wet True Density (g/ml) | 1.21 | 1.22 | 1.13 | 1.1 | |

| Wet Apparent Density (g/ml) | 0.78 | 0.79 | 0.69 | 0.71 | |

| Compressive Strength |

Average crush strength g/particle |

975 | 951 | 769 | 754 |

|

>500g/particle(cation) >200g/particle%(anion) |

100% | 100% | 100% | 100% | |

| Sphericity after Osmotic-attrition (%) | 99.7 | 99.8 | 99.4 | 99.6 | |

| The Whole Ball Rate(%) | 99.5 | 99.8 | 99.3 | 99.5 | |

| Hydrogen Form Rate(%) | 99.75 | 99.79 | —— | —— | |

| Hydroxide Form Rate (%) | —— | —— | 94.97 | 95.12 | |

| Impurity Content | Pbmg/kg dry resin | 0.3 | 0.4 | 0.3 | 0.3 |

| Almg/kg dry resin | 6.5 | 5.8 | 4.7 | 3 | |

| Femg/kg dry resin | 3.5 | 1.2 | 1 | 5.4 | |

| Cumg/kg dry resin | 7.6 | 7.2 | 9.1 | 7.6 | |

| Dissolved Matter (%)(dry resin) | 0.04 | 0.039 | 0.026 | 0.024 | |

| Transformation Expansion Rate (%) | 7.1 | 7.3 | 20.9 | 19.8 | |

| Heat Resistance (%) | —— | —— | 7.9 | 7.7 | |

| Determine Morphology | Hydrogen | Hydrogen | Hydroxide | Hydroxide | |

Table 2. Discharge Index of Condensate Refining

|

Hardness (μmol/L) |

Conductivity (μS/cm) |

Silicon dioxide (μg/L) |

Sodium (μg/L) |

Iron (μg/L) |

Copper (μg/L) |

|---|---|---|---|---|---|

| ≈0 | ≤0.15 | ≤15 | ≤5 | ≤8 | ≤3 |

Performance advantages of Sunresin condensate polishinguniformparticle super gel resin:

(1) It can provide better hydrodynamic characteristics and reduce the loss of system operating pressure.

The particle size evenness ratio of Sunresin condensate refining homogeneous super gel resin is less than 1.1. Its regular packing of resin bed avoids filling and blocking of bed voids by small particle resin, increasing effective circulation space and less pressure loss during system operation.

Comparison of pressure difference with varied particle sizes between conventional resin and homogeneous resin

(2) It has higher exchange speed and work exchange capacity.

Sunresin condensate refining homogeneous super gel resin can provide a larger contact surface area and a minimum ion diffusion path. Under the same working condition, it can significantly improve the ion exchange speed and the working exchange capacity. It fully meets the requirement of ion exchange removal precision in the process of high-speed condensate treatment.

(3) It has higher purity, less impurity dissolution, and maximum avoidance of impurity introduction in the finishing process.

The internal structure of Sunresin condensate refining homogeneous super gel resin is more regular and more uniform, and the residual organic and inorganic impurities of the resin after special process treatment are significantly reduced compared with conventional gel ion exchange resin and macroporous ion exchange resin, thus providing better purity guarantee for condensate refining.

(4) With high mechanical strength, it better meets that requirement of high-speed treatment of condensed water, with less resin breakage and longer service life.

Sunresin condensate refining homogeneous super gel resin has a special base ball synthesis process. The internal structure of the resin is more uniform, and the strength and toughness of the molecular framework are significantly improved and enhanced, so that it has better strength performance and permeability resistance. The crushing strength and permeability grinding ball index are significantly higher than those of conventional gel resin products, which can better meet the high-speed treatment conditions of condensed water, with less resin breakage and longer service life.

(5) In the regeneration process, anion and cation exchange resins have better separation effect and high regeneration efficiency.

Resin settling speed is a function of resin particle size and resin density. Under the inherent density difference between anion and cation exchange resins, the more uniform the particle size of the resin is, the better the anion and cation exchange resins can sink synchronously according to the differential speed, the fast and efficient bed separation between the anion and cation exchange resins can be realized, and convenient conditions are provided for the full regeneration of the resin in the later period.

(6) It has extremely high conversion rate of H-type/OH-type, with H-type rate >99% and OH-type rate >96%.