Sunresin Efficiency Chromatography Separation Technology and Application

Chromatographic separation is an efficient technique used to separate components from a complex mixture. This method relies on the distribution coefficient differences between the fixed phase and mobile phase of a chromatographic system. As the mobile phase moves through the system, the substances within it move along with it, repeatedly distributing between the fixed and mobile phases. This allows for the separation of different substances based on their unique elution spread distances.

Chromatographic separation is achieved by utilizing the selective distribution of different substances between stationary and mobile phases. A mobile phase is introduced to elute the mixture in stationary phase, causing different substances to move along the stationary phase at different speeds. This leads to the separation of components within the mixture. Chromatography can be classified into five types based on different separation mechanisms: adsorption, distribution, ion exchange, exclusion and affinity.

Simulated moving bed (SMB) chromatography system:

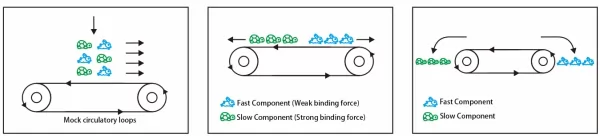

In a chromatographic separation, the components are separated through a stationary phase bed. Due to the different interactions between the components and the stationary phase, some components will elute faster than others, resulting in the separation of the mixture. If a counter-current flow is added during the elution process, as shown in the figure below with the race between the turtle and rabbit on a conveyor belt, the distance between them will increase, eventually leading to their separation. By continuously feeding rabbits and turtles at a certain position on the conveyor belt, continuous separation can be achieved. This is the principle behind the simulated moving bed (SMB) chromatography technique.

Simulated Moving Bed (SMB) Chromatographic separation technology characteristics:

Traditional industrial chromatography operates in a single-column, batch feed and elution mode, which results in low efficiency and severely restricts the industrial scale of chromatographic separation technology. This increases the equipment investment, space usage, and operational processing costs of industrial-scale chromatographic separation.

Sepsolut® Simulated Moving Bed (SSMB) Applications:

Sunresin has leveraged its technical expertise and experience in high-performance specialty resin development, as well as continuous ion exchange system design and manufacturing. Sunresin has developed a series of polymeric chromatography separation media and the versatile Sepsolut® simulated moving bed (SSMB) chromatography separation system based on the principle of SMB chromatography separation. By considering the separation performance characteristics of different products, Sunresin has successfully achieved industrial separations of sugar alcohols, amino acid purification, fermentation broth desalination and decolorization, and the separation of plant effective monomers. The separation efficiency of the system is stable, and the operation is smooth, which has been well received by customers.

DAC Industrial Preparative Chromatography:

DAC preparative chromatography is a technique that enables efficient sample separation. Due to the dynamic axial compression characteristic of DAC columns, higher theoretical plates and narrower peak widths can be achieved during the separation process, resulting in improved separation efficiency and peak capacity. When used in conjunction with chromatography separation resins by Sunresin, better separation results can be achieved, and complex mixtures can be separated.

DAC Chromatography Applications:

Due to the wide adaptability of DAC technology to different types of fillers, covering compounds with a wide range of molecular weights and various analytical applications such as liquid phase and solid phase separations, it offers advantages of efficient separation and low sample consumption. Moreover, due to the high separation efficiency and peak capacity of the DAC column during the separation process, the sample demand can be greatly reduced, making it particularly suitable for the analysis of compounds with scarce or high cost samples.

Sepsolut® High-Throughput Chromatography:

Sepsolut® high-throughput industrial preparative chromatography system, independently developed by Sunresin, is based on the DAC single-column chromatography system. It combines a series of polymer chromatography fillers with different matrices, different uses, and advantages such as high adsorption capacity, high anti-pollution performance, and alkali resistance regeneration. It can be used to purify high-purity substances from bulk mixtures, while balancing the advantages of high separation efficiency and industrial mass production, thus producing significant economic benefits.

_1698301937_WNo_600d368.webp)

Sepsolut® High-Throughput Chromatography Applications:

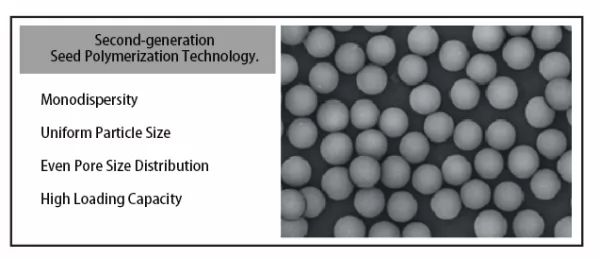

The chromatography fillers used in the Sepsolut® high-throughput chromatography system adopt the second-generation seed polymerization technology, which has the characteristics of monodispersity, uniform particle size, even pore size distribution, and high loading capacity. The entire system can achieve the separation of multiple components and obtain higher product separation purity. The system runs automatically and has full data traceability. It can provide high-pressure, low-pressure, and medium-pressure (50mm-1600mm) specifications and can be widely used in the separation and purification of pharmaceutical raw materials, nucleoside drugs, fine chemical products, plant active ingredients, proteins, as well as peptides and amino acids.

SSMB Sequential Simulated Moving Bed Chromatography System:

The SSMB sequential simulated moving bed chromatography system is an intermittent sequential operation simulated moving bed that combines the Monojet® series jetted particle chromatography fillers. Through the highly technological combination of equipment and control programs, it simulates the movement of the filler layer, adopts different operating modes of intermittent feeding and discharging with different sequences and programs, and adds separation ports that can be used for individual components to flow out, achieving the batch separation of 2-3 components. It has been successfully applied to the separation and purification of products such as sugar alcohols, amino acids, organic acids, and pharmaceutical intermediates.

SSMB Chromatography System Features:

The SSMB chromatography system has the following characteristics in large-scale batch product separation: high precision, high yield, and low water consumption. The equipment has strong versatility, and a set of equipment can achieve the separation of different products. It can also selectively increase the separation ports according to customer needs, achieving the separation of 2-3 different components.

SSMB Chromatography System Applications:

Separation of isomers mixtures as fructose/glucose, Psicose/fructose, mannitol/sorbitol, tryptophan/isoleucine, etc.

Separation of oligomers as oligofructose, oligo-galactose, inositol, resistant dextrin, lactulose, propylene glycol, etc.

Separation of organic molecules and salts as glycine, arginine, 1,3-propanediol, etc.

Separation of organic acids and inorganic acids/salts as citric acid, tartaric acid monoesters/diesters, succinic acid monoacid/polyacid, etc.

Sunresin can customize equipment and chromatography fillers according to customer requirements to meet specific application requirements. Relying on long term chromatography separation experience and a professional team, we can develop and optimize methods for specific samples and requirements of customers, select the best chromatography equipment and fillers to improve separation efficiency and precision, and achieve high-quality separation and purification results.