Sunresin Provides Customized Services and One-stop Separation and Purification Solutions for the Production of Allulose

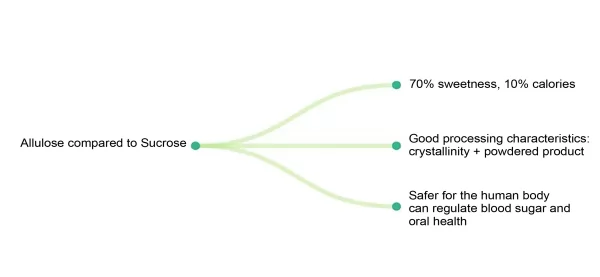

Allulose is a natural monosaccharide, an epimer of fructose, and a new type of low-calorie functional rare sugar.

Allulose is mainly produced industrially by biotransformation and has been approved for food use in the United States, Canada, Japan, South Korea and other countries. The performance of allulose among foods is equivalent to that of sucrose, and many studies have pointed out that multiple indicators of allulose have shown excellent properties in experiments.

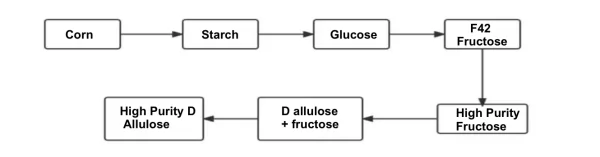

During the processing from the corn raw materials to the final allulose product, Sunresin provides a complete purification process including: ion exchange deashing, activated carbon decolorization, chromatographic separation, etc., to achieve high-quality crystalline allulose.

Currently, the two core process units in allulose production are the differential isomerization of fructose and the purification process.

Sunresin’s Sequential Simulated Moving Bed (SSMB) chromatography system and continuous ion exchange system can be used for the separation of allulose/fructose to obtain high-purity allulose products.

_1698306369_WNo_600d367.webp)

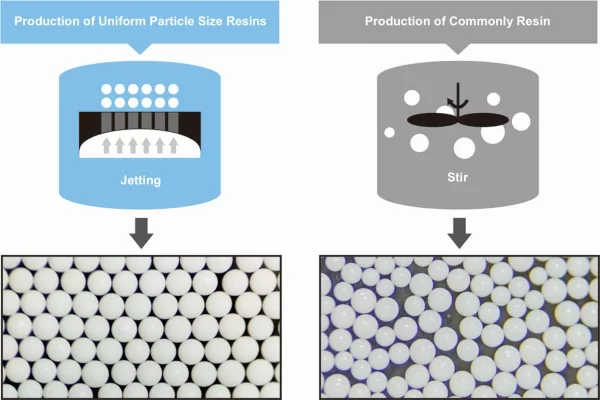

So far, Sunresin’s Sequential Simulated Moving Bed chromatographic device, combined with the Monojet Uniform Particle Size resins, through the smart combination of equipment and automatic control programs, simulates the movement of the resin layer, increases the separation nozzle for each component to flow out separately, realizes the batch separation of 2-3 components, and has been successfully applied to the separation and purification of sugar alcohols, amino acids, organic acids, pharmaceutical intermediates and other products.

Sunresin, driving the innovation.