Sunresin's Breakthrough in Medicinal Powder Resin Applications

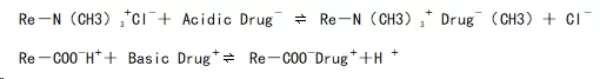

Sunresin is transforming pharmaceutical formulations with its innovative medicinal powder resins. These water-insoluble polymers feature a unique mesh-like structure capable of exchanging ions with those in a solution. Classified into cation and anion exchange resins based on the ions they exchange, and further distinguished by their acid-base properties into strong and weak acids or bases, these resins excel in enhancing drug efficacy. Their superior ion exchange capabilities enable rapid drug disintegration, controlled release, bitterness reduction, stability improvement, enhanced dissolution, and minimized adverse reactions. Ideal for a variety of dosage forms—ranging from tablets and capsules to gels and liquids—Sunresin's medicinal powder resins are a cornerstone of modern pharmaceutical development.

- Anion Exchange Resins: Proven to be effective in controlling hyperglycemia, showcasing their versatility beyond anion ion exchange functions.

- Cation Exchange Resins: These resins play a crucial role as supplementary treatments for secondary acute renal failure, especially notable in cases of anuria or oliguria, highlighting their life-saving potential.

- Cholestyramine Resin: This strong basic anion exchange resin is particularly used for mitigating pruritus in patients with high plasma bile salt levels, illustrating its unique application in alleviating discomfort associated with liver conditions.

Sunresin's proprietary strong cation exchange resins, featuring a robust polystyrene-divinylbenzene polymer skeleton, alongside our weak anion exchange resins, crafted from a polymethylacrylate-divinylbenzene skeleton, are pivotal in enhancing drug stability and facilitating sustained release. These resins excel in:

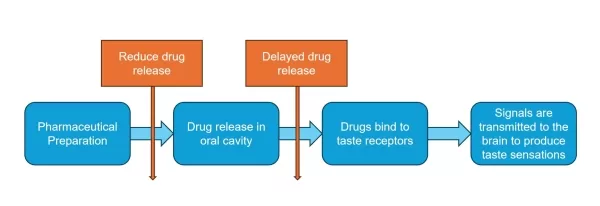

- Sustained and Controlled Release: Our resins form complexes with drugs to release them gradually, unaffected by dietary intake or pH levels, thus ensuring consistent therapeutic effects.

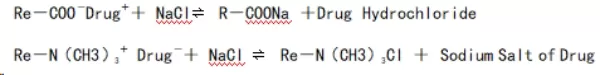

- Flavor Masking: By embedding drugs within our resin framework, we effectively mask their unpleasant tastes, significantly improving patient adherence to treatment regimens.

- Enhanced Drug Stability: Our resins protect drugs from environmental factors and interactions with other compounds, extending shelf life and maintaining efficacy.

- Promoting Drug Dissolution: By forming drug-resin complexes, we enhance the dissolution rate of drugs, ensuring faster and more complete absorption.

- Reducing Adverse Reactions: Our resins decrease the direct contact of irritant drugs with the gastrointestinal tract, minimizing the risk of ulcers and other adverse effects.

- Therapeutic Applications: Beyond their role in drug formulation, our ion exchange resins serve as active treatments for conditions like hyperacidity, ulcers, and kidney diseases, showcasing their versatility and therapeutic value.