Sunresin’s Sepsolut® SMB system in Vanadium extraction from stone coal

Vanadium is a silver-white refractory rare metal. It is ductile, hard, non-magnetic, and resistant to corrosion. Given its stable features in alkali, sulfuric acid and hydrochloric acid, it is widely used in machinery, automobile, shipbuilding, railway, aviation, bridge, electronic technology, national defense and other industries.

In nature, vanadium rarely exists alone. It forms symbiotic or composite ores with other minerals.Vanadium resources are mainly in two forms, vanadium-titanium magnetite and vanadium-bearing stone coal. Under the current technology, stone coals with a grade of vanadium pentoxide (V₂O₅) above 0.8% have mining values, accounting for about 20%-30% of the total stone coal reserves in China. This represents a higher recoverable reserves than from vanadium titanium magnetite.

In this article, we will walk you through Sunresin’s Sepsolut SMB technology in vanadium extraction from stone coal.

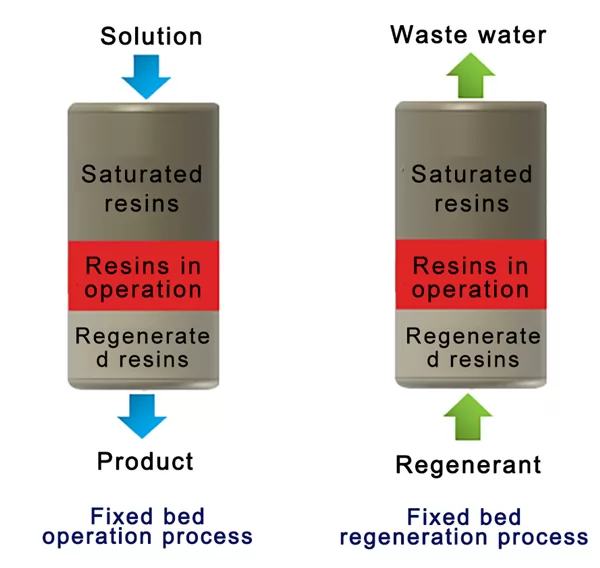

Traditional production lines of vanadium extraction from stone coal typically use a fixed bed system in manual mode. In order to meet the continuous operation of production, a minimum of 5 resin columns need to be equipped and divided into multiple operation groups, with each group being regenerated once every 10 to 12 hours. When production volume increases, it is necessary to increase the number of resin columns to dozens and the amount of resins required will also increase significantly. The result of this is a large portion of the resins will be in a standby mode, meaning the resin utilization efficiency is low.

With the fixed bed mode, in order to ensure the product quality, the resins cannot be used till saturation, thus further lowering its efficiency. Also, this leads to a bigger consumption of acid and alkali, and the generation of much more waste water, all of which lead to an increased production cost.

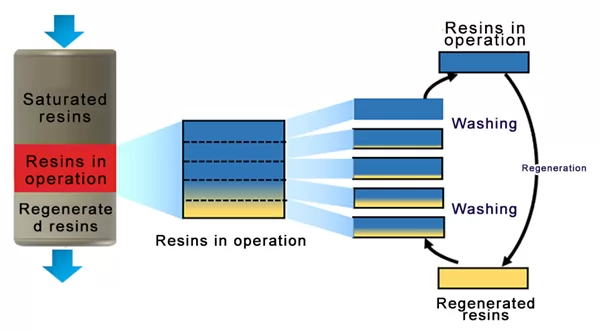

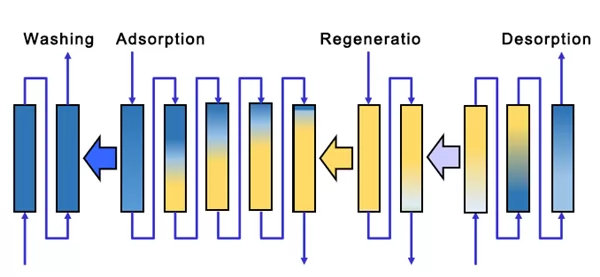

In order to solve the problem of inefficiency in the traditional fixed bed mode in vanadium extraction from stone coal, Sunresin has developed its Sepsolut SMB system, a 24/7 automatic operation system that improves resin efficiency and product quality, while reducing consumption and production costs, by turning large columns into smaller ones in series connection, with automated monitoring devices ensuring the smooth operation.

Reasonable design

Automatic control

Science-based experiments and computation

Top equipment integration technology

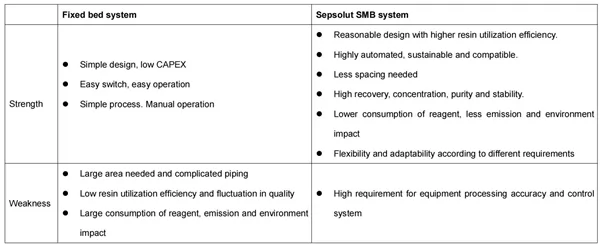

Comparison between Fixed Bed and Sepsolut SMB technologies:

From this comparison, we can conclude the following significant advantages of the Sepsolut SMB systme.

1.Lower consumption (50%-60%)

2.Highly automatic process without need for staffing

3.Reasonable valve array system ensuring inlet includes only precious liquid, acid, alkali and water, and outlet involves only poor liquid and desorbent without wastewater)

4.Tracability of production data