Sunresin Special Resin for Citric Acid Desalination, Decolorization and Refining

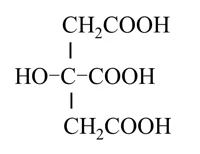

Citric acid, scientific name 2-hydroxypropane-1,2,3-tricarboxylic acid, is widely used in food, medicine, cosmetics and other industrial fields. The production of citric acid is mainly through biological fermentation. In the process of fermentation, salt, pigment and other impurities will inevitably be produced. It is necessary to achieve the impurity removal and purification of citric acid through necessary refining process to meet the requirements of relevant standards.

Chemical Formula of Citric Acid

Ion exchange resin process is a very effective and mature technology in the desalination and decolorization of citric acid, which is widely used in the industrial production of citric acid. However, the high osmotic pressure of citric acid will cause the repeated expansion and contraction of the resin in the refining process, and make the resin bear huge osmotic pressure, especially for the anion exchange resin, under this working condition, it is very easy to break the resin, affect the production, reduce the service life of the resin, and increase the cost. This has also become a universal problem that plagues the development of the industry, and there is a strong call for solutions.

Focusing on the specific problems and difficulties in this industry, Sunresin, based on the attitude of serving customers and promoting the development of the industry, relying on its strong product R & D ability and application technology strength, has successfully developed Seplite® LX-6703 especially for citric acid desalination, decolorization and refining with narrow particle size distribution, good penetration resistance and high exchange capacity. The resin has the features of strong processing capacity, low loss rate of citric acid, easy regeneration, low consumption of reagents, high mechanical strength, long service life, and higher accuracy of impurity removal. It has passed the production evaluation of industrial customers, and has been affirmed and recognized by customers.

Advantages of Seplite® LX-6703:

(1) Large volume exchange capacity, which can significantly reduce the production cost of enterprises;

(2) The exchange rate is fast and the ion removal precision is high, so the exchange capacity of chloride and sulfate is stronger and the precision is better;

(3) Special white beads process enables the resin matrix to have better resistance to high concentration of organic acid osmotic pressure, and still maintain good mechanical strength after long-term repeated regeneration;

(4) The resin channels are more well-distributed, and the resin is easy to regenerate. It is suitable for large-scale industrial citric acid production because of its long service life, short technological process, low operation difficulty and easy automatic control;

(5) The resin particle size is more uniform, which can bring better hydraulic properties in use, and the system pressure drop is smaller, making the resin especially suitable for continuous separation system with large pressure and load.