Sunresin Uniform Particle Chromatography Makes The Refining of Glucose Crystal Mother Liquor Simpler and More Efficient

Sunresin Uniform Particle Chromatography Makes The Refining of Glucose Crystal Mother Liquor Simpler and More Efficient

In the starch sugar industry, enzymatic degradation is used to convert starch into glucose. In the enzymatic degradation process, while converting starch into glucose, some isomer of glucose, fructose, is also produced. After purification, concentration and crystallization, glucose is precipitated as product crystals, while fructose is retained in the crystalline master liquor. However, there is still a considerable amount of glucose in the crystalline master liquor (the glucose content is generally 65%-75%). An efficient and convenient method is chosen to separate glucose and fructose in the crystallization master liquor and to realize the productization of glucose in the crystallization master liquor. It has become the key to efficiency and cost reduction in the starch and sugar industry.

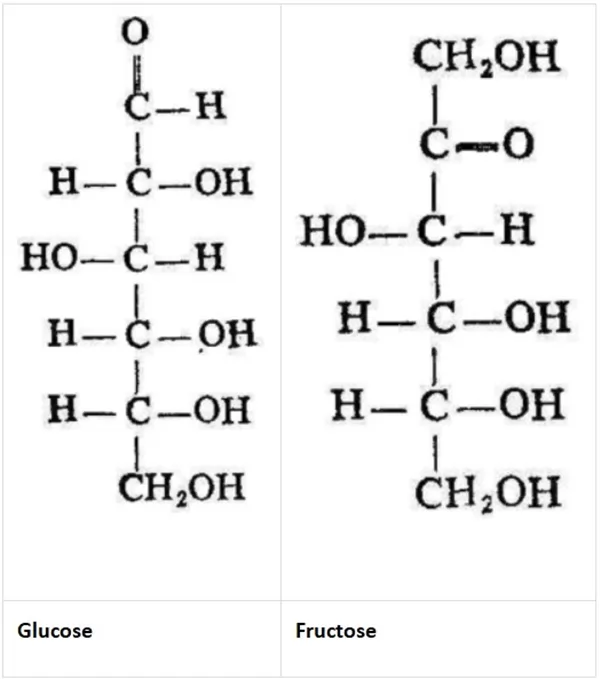

Glucose and fructose are both monosaccharides composed of six carbon atoms, but glucose is a polyhydroxy aldehyde structure, while fructose is a polyhydroxy ketone structure.

Based on the slight difference in the molecular structure of glucose and fructose, Sunresinselects Seplite® MonojetTM CM1850 uniform particle strong acid cation exchange resinproduced by advanced "jet granulation" technology after repeated tests and demonstrations. By using the special structural design and functional group setting of the resin, the binding force between the resin and glucose and fructose can be differentiated, and the efficient separation of glucose and fructose can be achieved through the elution of spreading agent according to the degree of difficulty of separation. At the same time, combined with Sepsolut® Simulated Moving Bed Chromatography (SMB/SSMB) technology developed by Sunresin, the stable and continuous industrial chromatographic separation can be realized. At present, Seplite® MonojetTM CM1850 resin with Sepsolut® simulated moving bed chromatography system has been applied in the industrial chromatographic separation of glucose and fructose in the crystalline mother liquor of many starch and sugar industries. With good operation and stable processing results, it has been unanimously approved by customers and make this field competely gets rid of the control from foreign products and technology.

_1698370573_WNo_600d362.webp)

Treatment effects:

(1) Feed indicators

| Feed flow | 6m³/h |

|---|---|

| Feed glucose content | 70-75% on DS |

(2) Material output indicators

| Discharge flow rate | 6m³/h |

|---|---|

| Output glucose content | >95.0% on DS |

Seplite® MonojetTM CM1850 uniform particle chromatography resin performance advantages:

(1) Truly homogeneous particle size; less pressure drop in the system operation during chromatographic separation.

(2) Good mechanical strength and impermeability; longer service life of resin.

(3) Higher working exchange capacity and exchange speed; higher processing efficiency and lower cost.

We are able to provide:

(1) chromatographic separation small pilot demonstration and pilot certification services.

(2) design of chromatographic separation processes

(3) high quality uniform particle chromatographic resin

(4) the provision of efficient simulation of moving bed chromatographic separation technology (SMB/SSMB) and complete system equipment

(5) related technical advice and debugging, and technical support services during the operation