A Sharp Tool for Volatile organic compounds (VOCs) Treatment: Sunresin VOCs Resin Adsorption Technology

The reasonable and effective treatment of waste water, waste gas and solid waste is the core of environmental protection work. With the in-depth development of national environmental protection work, the waste gas treatment work has gradually become the focus of environmental protection and attracted more and more attention, and the emission standard of volatile organic compounds in waste gas has become more and more strict. Volatile organic compounds (VOCs) are a kind of main air pollutants in the exhaust gas, mainly some low boiling point, volatile organic compounds, which are produced in the chemical production process of raw material reagents or solvents volatilization, which not only causes material loss to related production enterprises, but also brings difficulty to the treatment of exhaust gas.

At present, for waste gas treatment, there are mainly assimilation method, absorption method, combustion method, concentration method, degradation method and other common methods. In order to meet the treatment requirements, different treatment processes are often selected for combination. However, in the face of chlorinated hydrocarbon VOCs (such as dichloromethane, dichloroethane, chloroform, chlorobenzene, etc.), the combustion method can not be used for thorough treatment (on the one hand, it will cause equipment corrosion, on the other hand, it will produce dioxin, a highly biotoxic carcinogen with stable properties). Generally, the adsorption method can only be used for recovery. The common adsorption materials in the market generally have the problem of poor adsorption capacity for chlorinated hydrocarbons, which has become the core problem affecting the economic and efficient treatment of chlorinated hydrocarbon VOCs.

Focusing on the molecular structure characteristics of waste gas VOCs and the operating conditions of waste gas treatment, Sunresin has specially designed the molecular framework structure of resin, developed and produced the Seplite® CT-10 special resin for waste gas VOCs treatment and the Sepsolut® integrated system for waste gas VOCs treatment, providing customers with the overall solution for waste gas VOCs treatment. Industrial experience has proven that Sunresin Seplite® CT-10 resin and Sepsolut® VOCs integrated treatment system can effectively adsorb and recover VOCs of different working conditions, concentrations and types, and the adsorption and removal rate of VOCs containing chlorine is more than 99.9%. It recovers the lost raw materials, solvents and other resources while meeting the emission standards, and is highly recognized by relevant production enterprises and environmental protection companies It is a sharp tool in the field of VOCs treatment.

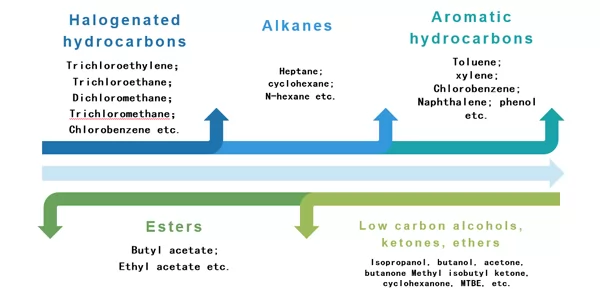

Applicable VOCs types for Seplite® CT-10 special resin and system of waste gas:

Advantages of Sunresin VOCs resin treatment process

(1)The resin is regular spherical bead with less wind resistance.

(2)The structure and performance of the resin are more stable. Acid resistance, alkali resistance and temperature resistance are better.

(3)The adsorption removal accuracy is higher (the adsorption removal rate can be more than 99%).

(4)The operation process does not need drying treatment, which can effectively reduce the adsorption heat and fundamentally eliminate the potential safety hazards.

(5)Resin loss is small, service life can be up to 5 years.

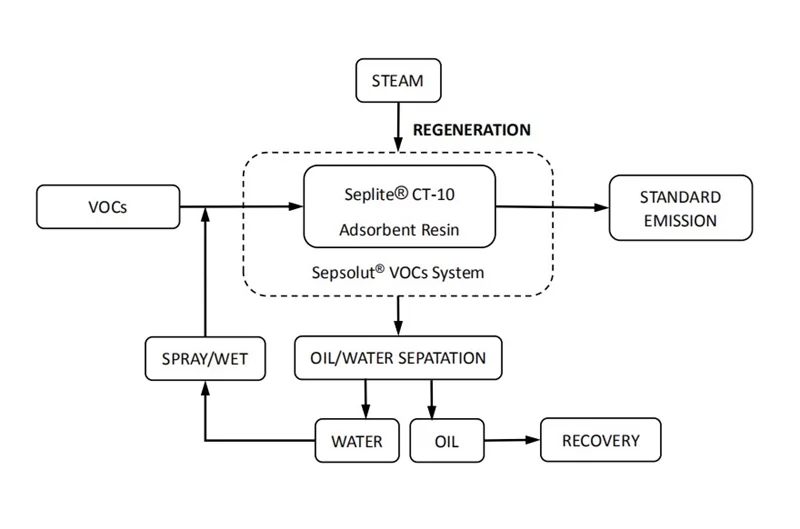

Process flow of Sunresin VOCs resin treatment: