Sunresin Xylitol Desalination and Decolorization Process Case

1. Natural Sweetener: Xylitol

Xylitol is a natural sweetener that's hard to extract but has lots of benefits. It's an organic compound that comes from Finland and is extracted from plants like birch trees, oak trees, corn cobs, and sugarcane bagasse. In nature, xylitol is widely distributed and found in various fruits, vegetables, and grains, but in low concentrations.

It's actually an intermediate in the body's normal carbohydrate metabolism, making it a great sugar substitute for people with diabetes. Xylitol has many functions, including sweetening, improving liver health, preventing tooth decay, aiding weight loss, and stabilizing blood sugar levels. It can be used as a substitute for sugar in households to prevent diabetes and obesity caused by excessive sugar consumption.

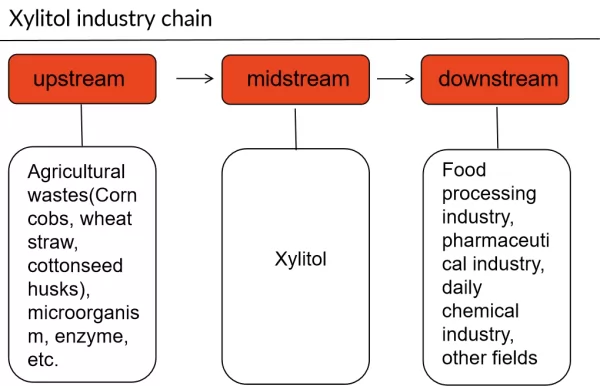

2. Upstream and downstream industrial applications of xylitol

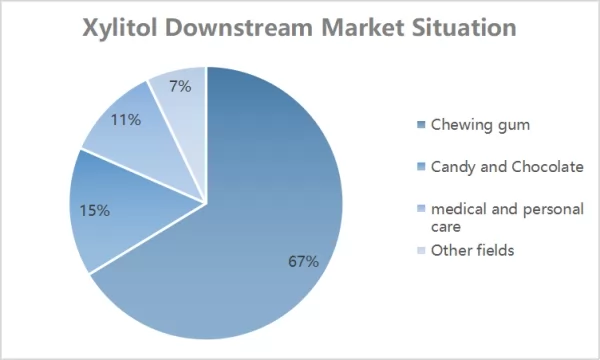

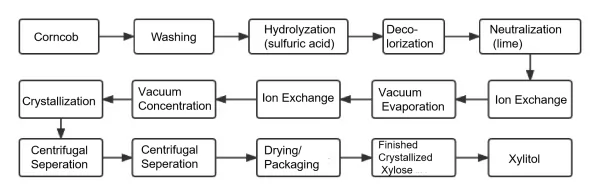

The xylitol industry chain is relatively simple. Upstream, the supply of raw materials relies mainly on agricultural waste materials rich in polysaccharides such as corncobs, wheat straw, cottonseed hulls, as well as microorganisms, enzymes, and other sources. The midstream industry consists of xylitol manufacturers and suppliers, while downstream users are primarily found in the food processing, pharmaceutical, daily chemical, and other industries. In the downstream market, xylitol is mainly used in candy, with various types of candy accounting for 78.65% of the market. In the global xylitol chewing gum sector, it holds the first place with a market share of 66.3%, followed by candy and chocolate with 15.3%, and medical and personal care with 11.3%. Other fields represent 7.1% of the market.

3. Current Status of the global and domestic xylitol industry

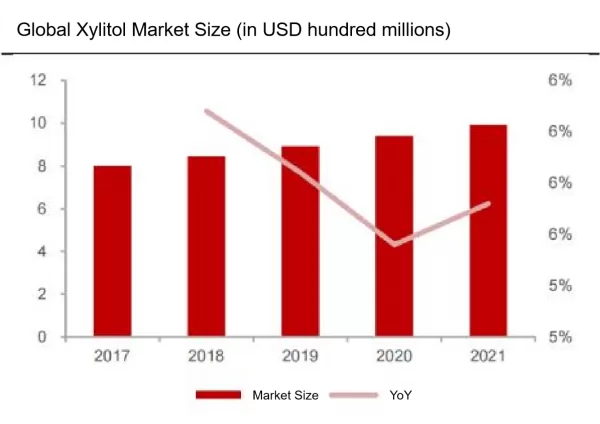

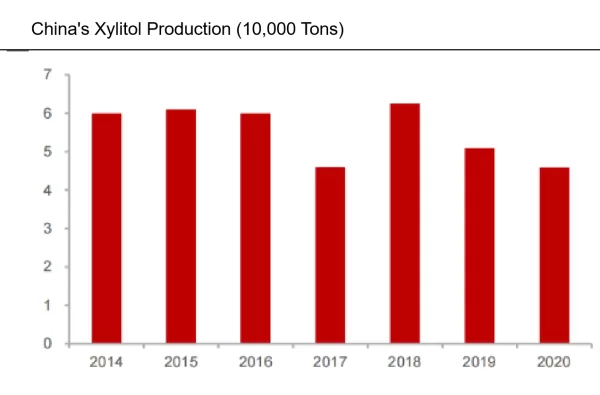

The global xylitol market size has been increasing year by year, while the xylitol production in China has been declining. The overall global xylitol market size has been on an upward trend, increasing from $800 million in 2017 to $993 million RMB in 2021, with a 5-year CAGR of 4.4%. The growth rate of the global xylitol market size has remained stable, with a steady increase of over 5% from 2018 to 2021, reaching 5.53% in 2021. It is estimated that the global xylitol market size will reach $1.11 billion in 2023, indicating significant market potential.

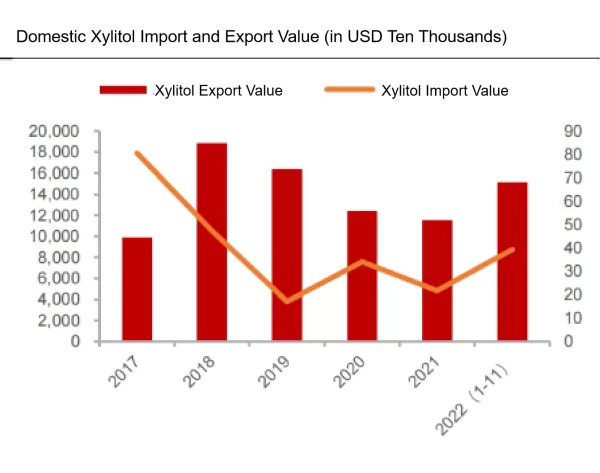

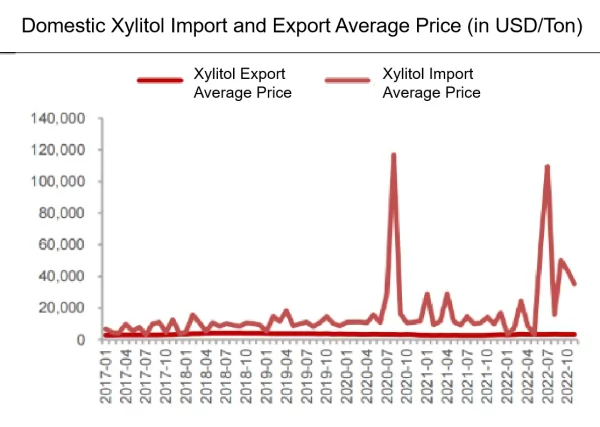

China is currently the world's largest producer and exporter of xylitol. Domestic xylitol exports generate significant revenue and have stable export prices. The import amount of domestic xylitol is relatively small, with the highest import amount being 805,600 USD in 2017 and the lowest being only 171,500 USD in 2019. This is mainly due to the large fluctuations in the import price of xylitol, which exceeded 100,000 USD/ton in 2020 and 2022. Additionally, the import price of xylitol is generally higher than the export price. Domestic xylitol exports generate more revenue, with export amounts generally exceeding 100 million USD, reaching 188 million USD in 2018 and 150 million USD in November 2022, far higher than the 115 million USD exported in 2021. The average export price of domestic xylitol is stable at 3,000 USD/ton, indicating a relatively stable income from exporting xylitol.

4. Xylitol production resin seleciton and process solutions

In response to the high osmotic pressure of sugar alcohol products on resins, Sunresin Technology has developed SEPLITE® Monojet™ LSF974 and SEPLITE® Monojet™ LSF9730 jetted uniform particle ion exchange resins, which are characterized by uniform particle size, good strength, and long service life. Additionally, the uniform particle size reduces the pressure drop in the resin bed, resulting in a higher online liquid processing capacity compared to conventional resins such as SEPLITE® LSF970 and SEPLITE® LSF973. The resin also has a lower breakage rate and a better impurity removal effect, which can significantly improve production efficiency and reduce production costs.

In addition, Sunresin has developed the SSMB continuous chromatographic salt separation process and continuous ion exchange process to address the common problem of high salt in hydrolyzed wood sugars such as corn cobs and sticky semi-fibers.

Sequential Simulated Moving Bed (SSMB) Continuous Chromatography Process: This process is designed for the separation of sugar and salt from xylose hydrolysate containing high salt and pigments, using customized chromatography resin and a system that utilizes the ion-exclusion mechanism of the resin. The entire process requires only pure water without any acid or alkali consumption, leading to the removal of over 90% of ash content and partial pigments. This reduces the load on subsequent ion exchange systems, lowers the resin usage, and consequently reduces the consumption of regenerating agents.

The continuous ion exchange process simulates resin column movement through valve arrays to improve resin utilization and efficiency. With the same production capacity, the resin usage is lower, and Multistage resin columns can use material, regeneration agent, and rinse water repeatedly, significantly reducing operating costs.

5.continuous ion exchange device application

To maximize the performance advantages of the resin, Sunresin designed a more advanced continuous ion exchange device. Through the matrix layout of self-controlled valves, it can quickly switch and reuse resin columns, greatly reducing the consumption of materials (acids, alkalis, water) during the production process.

The resin and equipment can run continuously, with high utilization, providing uninterrupted and stable feedstock for subsequent process segments. Compared with traditional fixed bed systems, resin usage can be reduced by 50-80% and regenerant usage can be reduced by 35-60%.