SEPLITE® Monojet™ Uniform Particle Polishing Resin, Ultra-pure Quality

In the production of electronic components, integrated circuits, chips and other electronic industries, almost every process requires pure water for cleaning operations and the workpiece is in direct contact with water. On the one hand, it can clean the stains in the process, on the other hand It is necessary to avoid impurities in water from forming secondary pollution to the workpiece. The concept of "electronic grade ultra-pure water" become one of the most important part of electronic industries.

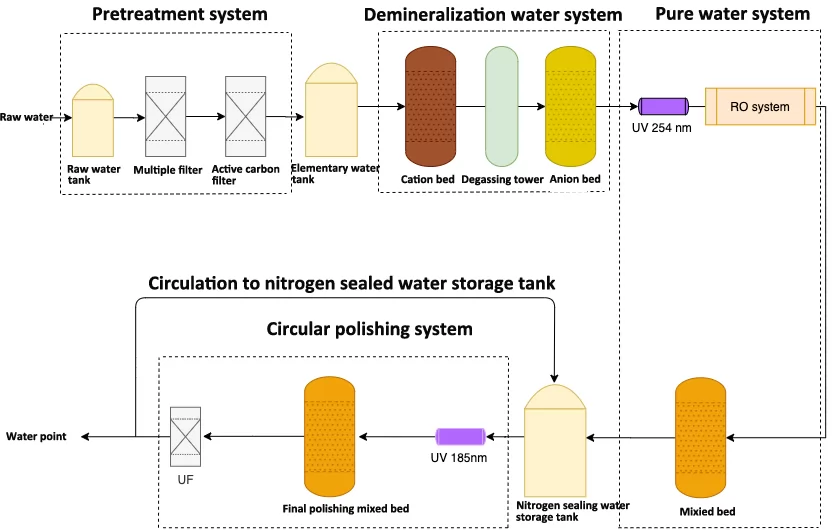

Traditional technological process for preparation of electronic grade ultrapure water:

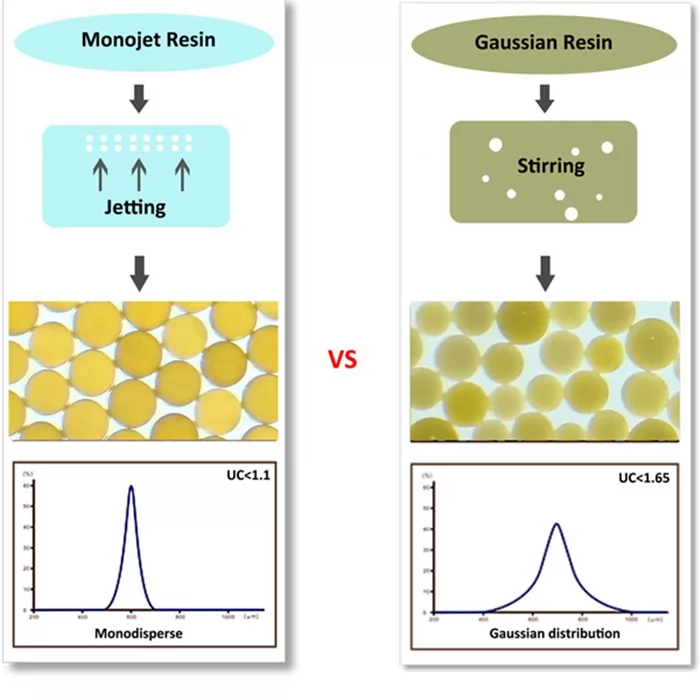

In the ultra-pure water preparation and polishing process, high-quality polishing resins with higher processing accuracy, higher purity level and uniform particle size are needed to achieve the purification of water. Sunresin have developed the "jet granulation" technology and uses the world's leading resin production line produced high-purity, high-transformation, uniform-grain H-type cation exchange resin and OH-type anion exchange resin with uniformity coefficient <1.1, which were pre-mixed in a certain proportion and used for the refining treatment at the end of ultrapure water preparation system. (Refined polishing process section)

Comparison between "jet granulation" process and traditional process:

Sunresin's refined polished resin type and water inlet and outlet indicators:

| Product | Inlet water specs | Outlet water specs |

|---|---|---|

| Seplite® Monojet™ MB615U |

Electrical resistivity> 16MΩ·CM |

Electrical resistivity> 18.1MΩ·CM |

| TOC<20ppb | TOC<2ppb | |

| Si<5ppb | Si<1ppb | |

| Seplite® Monojet™ MB610U |

Electrical resistivity> 17MΩ·CM |

Electrical resistivity> 18.2MΩ·CM |

| TOC<15ppb | TOC<2ppb | |

| Si<2ppb | Si<0.5ppb |

Advantages of Sunresin's refined polishing resin:

1. With better fluid dynamics, the system operates with less pressure drop. Sunresin's polishing resin uses gel anion and cation resins with uniform particle size, and the uniformity coefficient is less than 1.1. When filling, it avoids the filling of voids with small particles of resin, increases the effective space, and reduces the fluid resistance significantly.

2. Have a higher exchange speed and work exchange capacity. Under the same processing conditions, the uniform particle resin can provide a larger resin surface area and the smallest ion diffusion path, significantly improving the resin exchange speed and working exchange capacity.

3. Better mechanical strength and less loss of resin crushing during operation.

4. Higher purity and extremely low impurity ion content.

5. Very high H-type / OH-type conversion rate, H-type rate> 99%, OH-type rate> 96%.

6. Short supply cycle, better meet customer needs.