Use of Citric Acid and Sunresin’s Technology in Demineralization and Decolorization

Citric acid (C6H8O7) is a weak organic acid found naturally in citrus fruits like lemons, limes, oranges, and grapefruits. It is a white crystalline powder that has a sour taste and is commonly used as a food preservative, flavoring agent, and acidulant in a variety of food and beverage products. Citric acid is also used in many cleaning products as a chelating agent to remove limescale and rust stains. Additionally, citric acid is used in the pharmaceutical industry as an excipient in medicines and in cosmetics as a pH adjuster and preservative.

Food and beverages:

Citric acid has a mild and refreshing sour taste, and is widely used in the manufacture of various beverages, candies, biscuits, juices, dairy products and other foods. In the market of all organic acids, citric acid has a market share of more than 70%. So far, no sour agent can replace citric acid.

_1698305846_WNo_600d399.webp)

Citric acid can be obtained as an anhydrous (water-free) form or as a monohydrate. The monohydrate citric acid is mainly used as an acidic flavoring agent for cool drinks, fruit juices, jams, fruit sugar and canned food, etc. It can also be used as an antioxidant for edible oils, improving the sensory properties of food, enhancing appetite and promoting digestion and absorption of calcium and phosphorus substances in the human body.

Anhydrous citric acid is widely used in solid beverages. Salts of citric acid, such as calcium citrate and ferric citrate, are fortifiers for some food that needs to add calcium ions and iron ions. Esters of citric acid, such as triethyl citrate, can be used as non-toxic plasticizers, and are used to make plastic films for food packaging.

Pharmaceuticals:

In the pharmaceutical industry, citric acid can react with sodium carbonate or sodium bicarbonate aqueous solution to produce a large amount of CO2, which is used as an effervescent system, so that the active ingredients of the drug can be dissolved rapidly and the taste effect can be improved.

Citric acid can also be used as a buffer in various nutritional oral solutions.

Adding a small amount of citric acid to traditional herbal medicine preparations can form trace amounts of iron-copper metal complexes, delaying the degradation of active ingredients.

Various salts of citric acid can also help the body supplement the corresponding elements. Sodium citrate is an anticoagulant widely used in blood transfusion, preservation of blood and plasma, and processing of artificial plasma and blood products.

Cosmetics:

Citric acid is a kind of fruit acid, which is often used in lotion, cream, shampoo, anti-aging products, etc. Its main function is to accelerate the renewal of cutin, which helps the metabolism of melanin in the skin, dissolves blackheads, improves pores, and also moisturizes the skin to a certain extent.

Poultry production:

Adding citric acid to piglet feed can reduce the diarrhea rate of piglets (early weaned piglets have low disease resistance and high mortality due to diarrhea), so that piglets can be weaned early and increase the litter size of sows.

Adding 1% to 2% citric acid to the diet of growing pigs can increase the daily gain of weight, reduce the thickness of back fat, and improve meat quality.

Rare earth citrate is a new type of high-efficiency feed additive, suitable for various animals such as pigs, chickens, fish, shrimps, cattle, sheep, rabbits, silkworms, etc. It can promote animal growth, improve disease resistance and survival rate, improve feed conversion rate and shorten the feeding cycle.

Chemical and textile industries:

Citric acid can be used as chemical analysis reagent in chemical technology, as experimental reagent, chromatographic analysis reagent and biochemical reagent, complexing agent, masking agent, or used to prepare buffer solution.

Citric acid can also be used as a reagent for testing the acid resistance of architectural ceramic tiles. Using citric acid or citrate as a builder can improve the performance of washing products, rapidly precipitate metal ions, prevent pollutants from reattaching to fabrics, and maintain washing-essential alkalinity.

Formaldehyde pollution of clothing is a very sensitive issue, and citric acid and modified citric acid can be made into a formaldehyde-free anti-wrinkle finishing agent for anti-wrinkle finishing of pure cotton fabrics.

The fermentation and extraction of citric acid:

Fermentation of citric acid:

1)The solid-state fermentation method uses dried potato powder, starch meal and starchy agricultural and sideline products as raw materials. After preparing the culture medium, it is cooked under normal pressure, cooled to the inoculation temperature, inserted into the seed koji, put into the koji plate, and fermented under certain temperature and humidity conditions. The production of citric acid by solid-state fermentation uses simple equipment and is easy in operation.

2)The liquid shallow plate fermentation method mostly uses molasses as raw material. The production method is to transfer the sterilized culture solution into each fermentation plate through pipelines, insert the bacteria, and add sugar solution to ferment after the bacteria form a bacterial film. For this method, fermentation requires sterile air to be introduced into the fermentation room.

3)In submerged fermentation, the main equipment for the production of citric acid is the fermenter. Microorganisms reproduce and ferment in this airtight container.

Extraction of citric acid:

In addition to the main product, the citric acid fermentation broth also contains other metabolites and some impurities, and the citric acid must be extracted by physical and chemical methods. The main methods of separation and purification of citric acid are the calcium salt method and chromatography method.

The calcium salt method is to change the citric acid in the fermentation broth into calcium salt precipitation, replace the calcium citrate with free citric acid with sulfuric acid, and precipitate the generated calcium sulfate, and then further purify and crystallize the citric acid. However, the calcium salt method has the following disadvantages:

Complicated and inconvenient processes

Low yield (about 80-85%)

Environmental concern with a large amount of calcium sulfate waste being produced

Continuous chromatography is a new technology with high separation efficiency, which makes up for the shortcomings of the traditional technologies such as non-continuous operation and low utilization rate. It has been widely used in the fermentation industry, including in recent years, in the citric acid industry.

The continuous chromatography technology has the following advantages:

Simple process, high degree of automation and low cost;

High yield (over 90%);

Environment friendly with no solid waste such as calcium sulfate being produced and reduced cost for waste treatment.

Special resins for citric acid desalination and decolorization:

The ion exchange process is an effective and mature process technology in the demineralization and decolorization of citric acid, and is widely used in the industrial production of citric acid.

However, the high osmotic pressure of citric acid causes repeated expansion and contraction of the resins during the fine purification process, and makes the resins bear a huge osmotic pressure, especially for anion exchange resins. Under this condition, the resins can be easily broken, reducing the service life of the resins and increasing the cost. This has become a common problem that holds back the development of the industry, and there was a strong call for a solution.

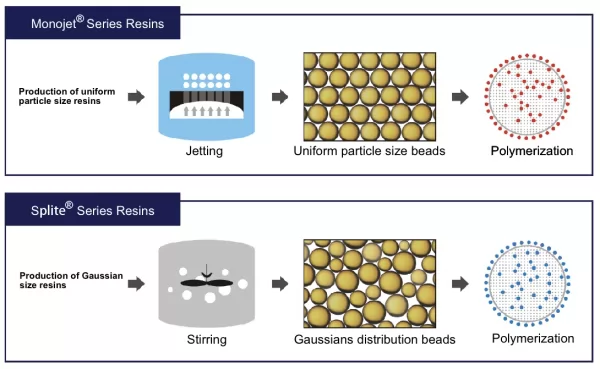

In response to this difficulty, Sunresin has successfully developed the acrylic based weak base anion exchange resin with uniform particle size distribution, good osmotic pressure resistance and high exchange capacity, which is used for the demineralization and decolorization of citric acid.

This resin has the advantages of strong processing capacity, low citric acid loss rate, easy regeneration, reduced reagent consumption, high mechanical strength, long service life, higher precision of impurity removal, and has been highly affirmed and recognized by the industry.

Sepsolut SMB System:

In order to maximize the performance advantages of the resins, Sunresin combined the process characteristics of citric acid production and designed a continuous ion exchange SMB system with more advanced technology. Through the matrix arrangement of automatic control valves, the resin columns can be quickly switched and reused, significantly reducing the consumption of acid, alkali and water.

With Sunresin’s Sepsolut SMB system, the resins and equipment run continuously at a high utilization rate, providing uninterrupted and stable feed liquid for subsequent sections. Compared with the traditional fixed bed system, the amount of resins used can be reduced by 50-80%, while the amount of regenerant can be reduced by 35-60% %, helping the citric acid industry to move forward more efficiently.