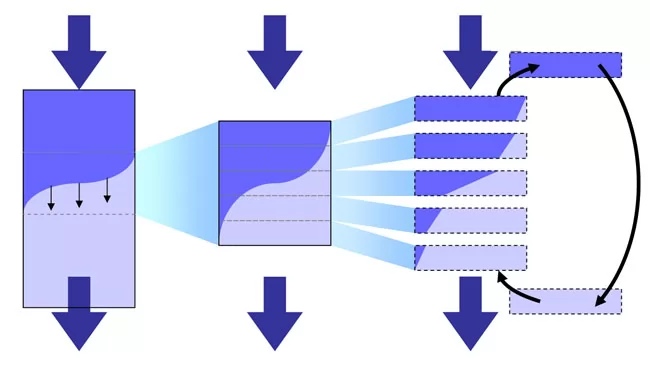

What is Simultaneous Moving Bed?

The whole section of resin in the original fixed bed is divided into several sections, and different sections of resin play different roles at the same time, so that the various sections of the original fixed bed adsorption, washing, desorption, regeneration and the like are integrated into one system equipment. By using the part of the resin that was originally idle, this greatly improves the resin utilization rate while reducing the chemical consumption through an effective connection operation mode.

_1698384927_WNo_650d411.webp)

Advantages

-

Integrate all steps, continuous operation, and strong system matching.

-

Compact structure, less piping and less floor space.

-

High resin utilization.

-

High product yield, concentration and purity, and good stability.

-

Less water and chemical reagents.

-

Good operational flexibility according to the change of production load.

-

Adjust valve switching speed or adjust flow rate.

-

Three wastes are rarely emitted, reducing environmental pressure.

Typical Applications

-

Amino acid purification

-

Fruit juice fructose desalting and bleaching

-

Extraction of vitamin C

-

Lactic acid purification

-

Extraction of gallium from fly ash alumina

-

Citric acid purification

-

Separation of fructose syrup

-

Preparation of lithium carbonate in brine

-

Xylose preparation

-

Preparation of iohexol